Gear Shaper Cutters

S.S. Tools is a pioneer and market leader for high accuracy gear shaper cutters.

The company manufactures various types of shaper cutters for spur or helical gears, involute splines, straight splines, chain sprockets, timing belt pulley and special profiles with missing teeth. The latest in-house design software and manufacturing capabilities enables S.S. Tools to deliver customised shaper cutters, assuring close dimensional accuracies to meet customer specifications.

These shapers are available in disc, shank, hub, extended back boss (EBB) type, etc. Cutters can be supplied with various profile features such as semi-topping, protuberance, topping, tip-relief, etc. as per customer requirement.

| Parameter | Details / Options |

| Material | Conventional / PM High Speed Steels are available including: M35 / S290 / S390 / ASP 2030 / ASP 2052 / ASP 2060 |

| Module Range | 0.5 – 16 mm |

| Accuracy Class | Class AA / A / B (as per DIN 1829) |

| Type | Disc Type, Hub Type, Shank Type, etc. |

| Profile modifications | Tip Relief / Protuberance / Semi-topping / Topping / Undercut Lugs etc. |

| Bores | 16, 22, 25.40, 27, 31.75, 32, 40, 44.45, 60mm etc. |

| Shank Sizes | Morse taper 1, 2, 3, 4 & 5; Fellows taper 1 & 2; cylindrical φ17.46, φ25.00, φ25.40 and φ32.00 |

| Coating Options | All common PVD coatings: TiN, Alcrona ® and Altensa ® |

| Application | Internal and External Gear Cutting |

| Tooth Form | Involute, straight flank, parallel sided keyways and non-involute (chain wheel, timing belt pulley, etc.) |

| Application Industries | Automotive, Heavy Engineering, Aerospace, Railways, Wind Turbines, etc. |

| Delivery Time | 2–4 weeks (standard); 4–6 weeks (custom) |

Material : Conventional / PM High Speed Steels are available including: M35 / S290 / S390 / ASP 2030 / ASP 2052 / ASP 2060

Module Range : 0.5 – 16 mm

Accuracy Class : Class AA / A / B (as per DIN 1829)

Type : Disc Type, Hub Type, Shank Type, etc.

Profile modifications : Tip Relief / Protuberance / Semi-topping / Topping / Undercut Lugs etc.

Bores : 16, 22, 25.40, 27, 31.75, 32, 40, 44.45, 60mm etc.

Shank Sizes : Morse taper 1, 2, 3, 4 & 5; Fellows taper 1 & 2; cylindrical φ17.46, φ25.00, φ25.40 and φ32.00

Coating Options : All common PVD coatings: TiN, Alcrona ® and Altensa ®

Application : Internal and External Gear Cutting

Tooth Form : Involute, straight flank, parallel sided keyways and non-involute (chain wheel, timing belt pulley, etc.)

Application Industries : Automotive, Heavy Engineering, Aerospace, Railways, Wind Turbines, etc.

Delivery Time : 2–4 weeks (standard); 4–6 weeks (custom)

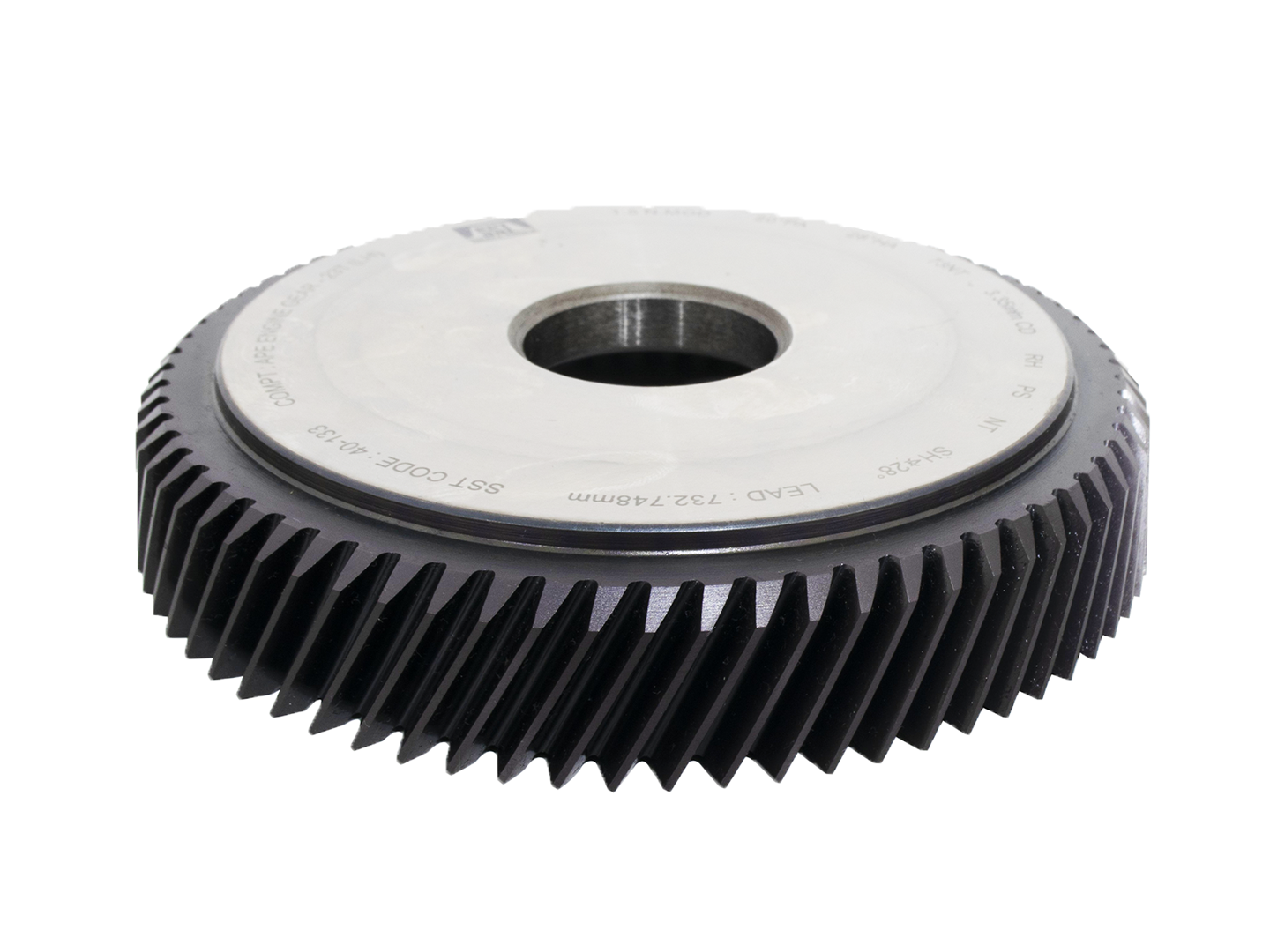

Disc Type Gear Shaper Cutters

Disc-type Gear Shaper Cutters are manufactured to produce spur or helical gears, involute splines, straight splines and sprockets. These cutters are produced as per standard design and also to suit specific customer drawings / specifications.

Shank Type Gear Shaper Cutters

These are designed and produced with high accuracy. Shank Type Gear Shaper Cutters are mainly used for cutting internal gears having small diameters. These cutters can be supplied for spur or helical gears, splines and serrations.

Helical Type Gear Shaper Cutters

Helical gear shaper cutters are produced with high accuracies to suit customer specific requirements. These tools can be supplied with special profile features like pre-shaving, protuberance, semi-topping, etc. and are being mainly used in the automotive gear industry.

Extended Back Boss Type Gear Shaper Cutters

This type of tool is necessitated where disc-type cutters cannot be used. In these cutters the clamping nut does not interfere with the fixture on the work-piece.

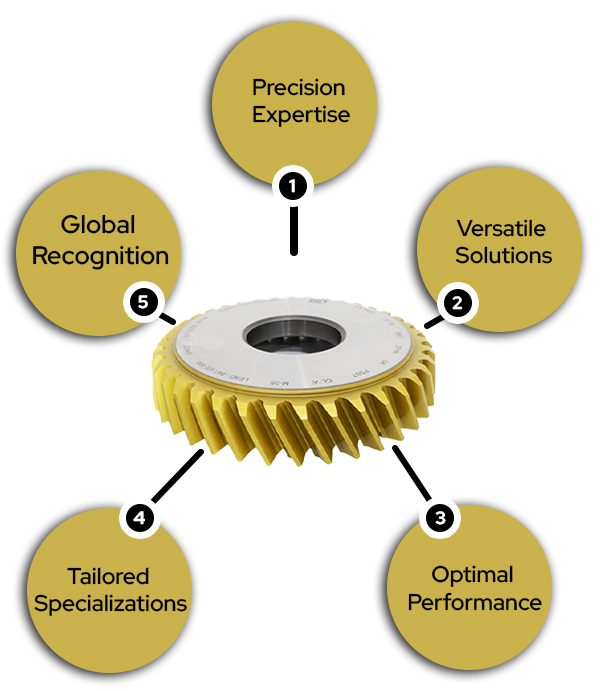

Benefits of Gear Shaper Cutters

Gear Shaper cutters offer precision, enhancing the performance and durability of gears in various applications. Let’s look at why these cutters are so beneficial.

- Precision Expertise: S.S. Tools, a pioneering force in shaping cutters, ensures exceptional accuracy and dimensional perfection through its gear shaper cutters. This dedication caters to diverse customer needs.

- Versatile Solutions: The collection offered provides an array of gear shaper cutter options for various gears, splines, and sprockets. Configurable selections effectively address industry-specific requirements.

- Optimal Performance: The gear shaper cutters stand out in durability, enhancing gear cutting efficiency and lifespan. Premium materials like PM and HSS grade steels and coatings like Alcrona Pro contribute to this top-tier performance.

- Tailored Specializations: With specialized options like helical and extended back boss cutters, specific demands like automotive gear manufacturing are met with finesse.

- Global Recognition: S.S. Tools stands tall as one of the preeminent gear shaper cutters supplier in India and beyond, renowned for delivering high-quality products. Their influence spans across markets in India and other countries, setting a benchmark for excellence in the industry.

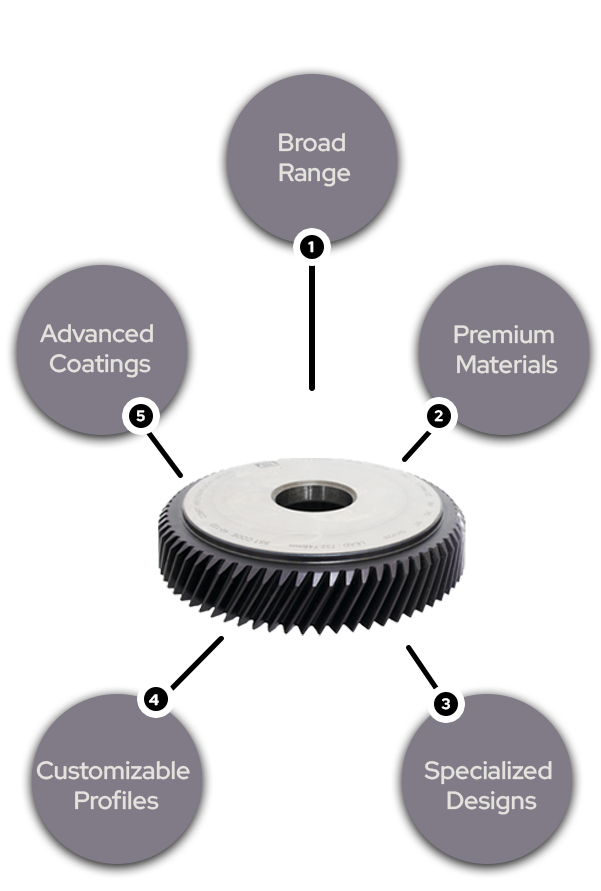

Features of Gear Shaper Cutters

The features extend to you the high-quality, versatile, and precision-driven nature of the tool. The following are the features of the gear shaper cutter:

- Exceptional Precision: Certified to class AA and A as per DIN 1829, it ensures high dimensional accuracy.

- Variety of Types: Includes disc-type, shank-type, helical-type, and extended back boss (EBB) cutters to cover all needs.

- Customizable Profiles: Available with semi-topping, protuberance, topping, and tip-relief features for tailored solutions.

- Broad Range: Suitable for modules (DP) from 0.5 to 16 and diameters from 10 to 250 mm.

- Premium Materials: Made from high-speed steels and powder metallurgy steels like ASP 2060 and S390 for durability.

- Advanced Coatings: Options include Gold (TiN), Futura Nano (TiAlN), and Alcrona (AlCrN) for enhanced wear resistance.

- Specialized Designs: Offers specific cutters for internal gears, automotive needs, and where disc-type cutters are unsuitable.

- Global Expertise: Recognized for high-quality, precision gear shaper cutters, serving markets in India and internationally.

Additional Must Notes

When choosing gear shaper cutters, consider their suitability for your specific application.

- Ensure the tool’s material and coating meet high-quality standards.

- Follow compatibility with your gear shaper machine and fixtures.

- Explore custom options for better efficiency and weigh the cost against the benefit.

- Proper operator training is crucial.

- Ensure the cutters meet industry-specific standards for regulatory compliance.

FAQ's

A gear shaper cutter is a tool used in gear manufacturing to cut different types of gear teeth with precision.

When selecting a gear shaper cutter, consider:

- Precision and accuracy

- Cutter type and size

- Material and coating

- Durability and performance

- Customization for need

- Maintenance requirements

Maintaining them involves regular cleaning to prevent any buildups and corrosion. It includes regular checks for wear, tear, and damage. You must store them in a clean and dry environment and re-sharpen them for efficiency and accuracy. Also, apply lubricants for a smooth operation.

Gear shaper cutters are more precise in internal and external gear cutting, and handling complex profiles. They use reciprocatory motion over rotary motion for seamless production.

While using gear shaper cutter, ensure to:

- Use safety glasses, gloves, and hearing protection to safeguard against debris and noise.

- Inspect the cutter and machine for their condition and check their maintenance before use.

- Properly clamp and secure workpieces to prevent movement during cutting and adhere to the manufacturer’s instructions.

- Keep loose clothing and hair away from moving parts and familiarize yourself with emergency stop functions.