Gear Shaper Cutters

S.S. Tools is a pioneer and market leader for high accuracy gear shaper cutters.

The company manufactures various types of shaper cutters for spur or helical gears, involute splines, straight splines, chain sprockets, timing belt pulley and special profiles with missing teeth. The latest in-house design software and manufacturing capabilities enables S.S. Tools to deliver customised shaper cutters, assuring close dimensional accuracies to meet customer specifications.

These shapers are available in disc, shank, hub, extended back boss (EBB) type, etc. Cutters can be supplied with various profile features such as semi-topping, protuberance, topping, tip-relief, etc. as per customer requirement.

Module (DP) Range: 0.5 – 16 Mod. (DP 50 –1.5)

Diameter Range: 10 – 250 mm

Accuracy: Certified class AA, A as per DIN 1829.

Materials: Conventional / PM High Speed Steels are available including: ASP 2060 / ASP 2052 / ASP 2030 / S390 / S290 / M35

Coatings: All types of PVD coatings are available including: Gold (TiN) / Futura Nano (TiAlN) / Alcrona (AlCrN)

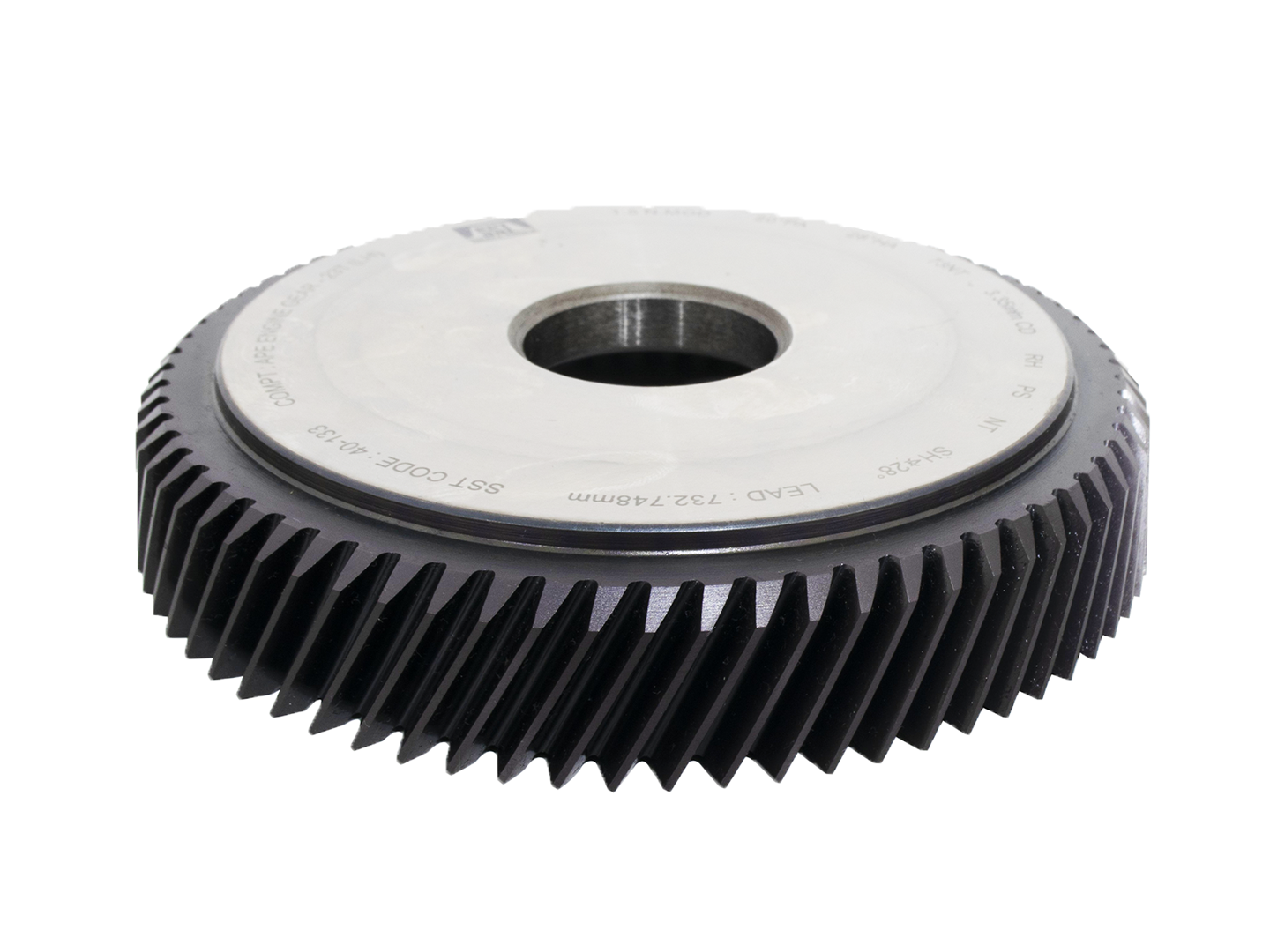

Disc Type Gear Shaper Cutters

Disc-type Gear Shaper Cutters are manufactured to produce spur or helical gears, involute splines, straight splines and sprockets. These cutters are produced as per standard design and also to suit specific customer drawings / specifications.

Shank Type Gear Shaper Cutters

These are designed and produced with high accuracy. Shank Type Gear Shaper Cutters are mainly used for cutting internal gears having small diameters. These cutters can be supplied for spur or helical gears, splines and serrations.

Helical Type Gear Shaper Cutters

Helical gear shaper cutters are produced with high accuracies to suit customer specific requirements. These tools can be supplied with special profile features like pre-shaving, protuberance, semi-topping, etc. and are being mainly used in the automotive gear industry.

Extended Back Boss Type Gear Shaper Cutters

This type of tool is necessitated where disc-type cutters cannot be used. In these cutters the clamping nut does not interfere with the fixture on the work-piece.

Menu

Benefits of Gear Shaper Cutters

Gear Shaper cutters offer precision, enhancing the performance and durability of gears in various applications. Let’s look at why these cutters are so beneficial.

Precision Expertise: S.S. Tools, a pioneering force in shaping cutters, ensures exceptional accuracy and dimensional perfection through its gear shaper cutters. This dedication caters to diverse customer needs.

Versatile Solutions: The collection offered provides an array of gear shaper cutter options for various gears, splines, and sprockets. Configurable selections effectively address industry-specific requirements.

Optimal Performance: The gear shaper cutters stand out in durability, enhancing gear cutting efficiency and lifespan. Premium materials like PM and HSS grade steels and coatings like Alcrona Pro contribute to this top-tier performance.

Tailored Specializations: With specialized options like helical and extended back boss cutters, specific demands like automotive gear manufacturing are met with finesse.

Global Recognition: S.S. Tools stands tall as one of the preeminent gear shaper cutters supplier in India and beyond, renowned for delivering high-quality products. Their influence spans across markets in India and other countries, setting a benchmark for excellence in the industry.

- A-6 Focal Point Patiala, Punjab – 147 004 (India)

- Mobile: +91 9915442200

- Tel : +91-175-2351272, 2354272

- Fax : +91-175-2361272

- E-mail : info@sstools.net

- E-mail : sstools1@gmail.com

- Website : www.sstools.net

Quick Links

Menu

Copyright © 2023 S.S. Tools. All rights reserved.