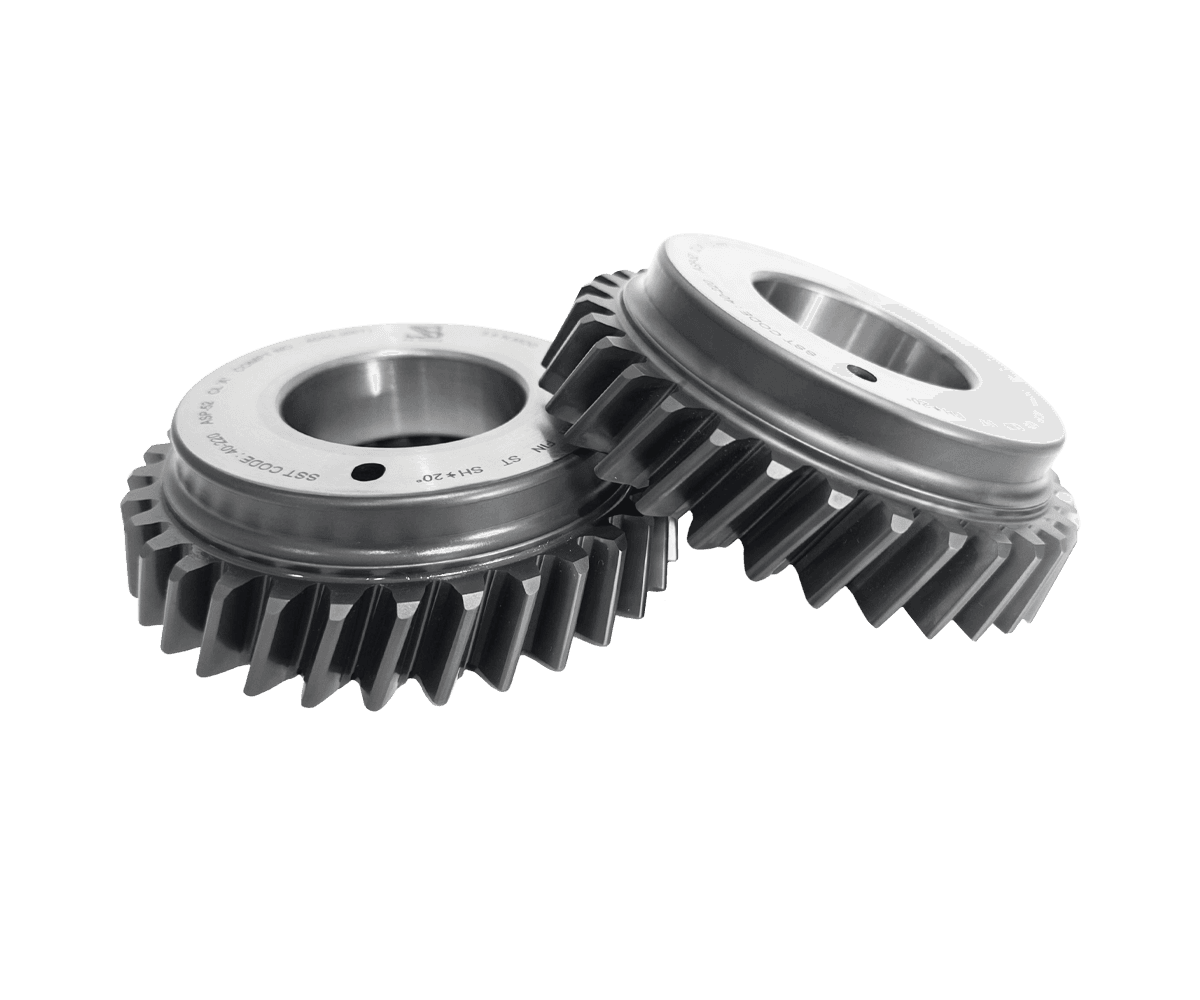

Skiving Cutters

S.S. Tools has recently added Skiving Cutters to their product portfolio and are now manufacturing this tool for the global market.

Power Skiving process includes continual gear cutting, making possible the production of both spur and helical in external and internal gears. A great advantage of Skiving Cutters is that they are quicker, more efficient and productive when compared to shaper cutters and broaches and allows for coolant-free machining. Also, the high number of cuts per time unit possible with these cutters not only leads to a very short cycle time but they also produce high-quality gears with low surface roughness.

This tool can be used on special skiving machines and multi-task CNC machining centres.

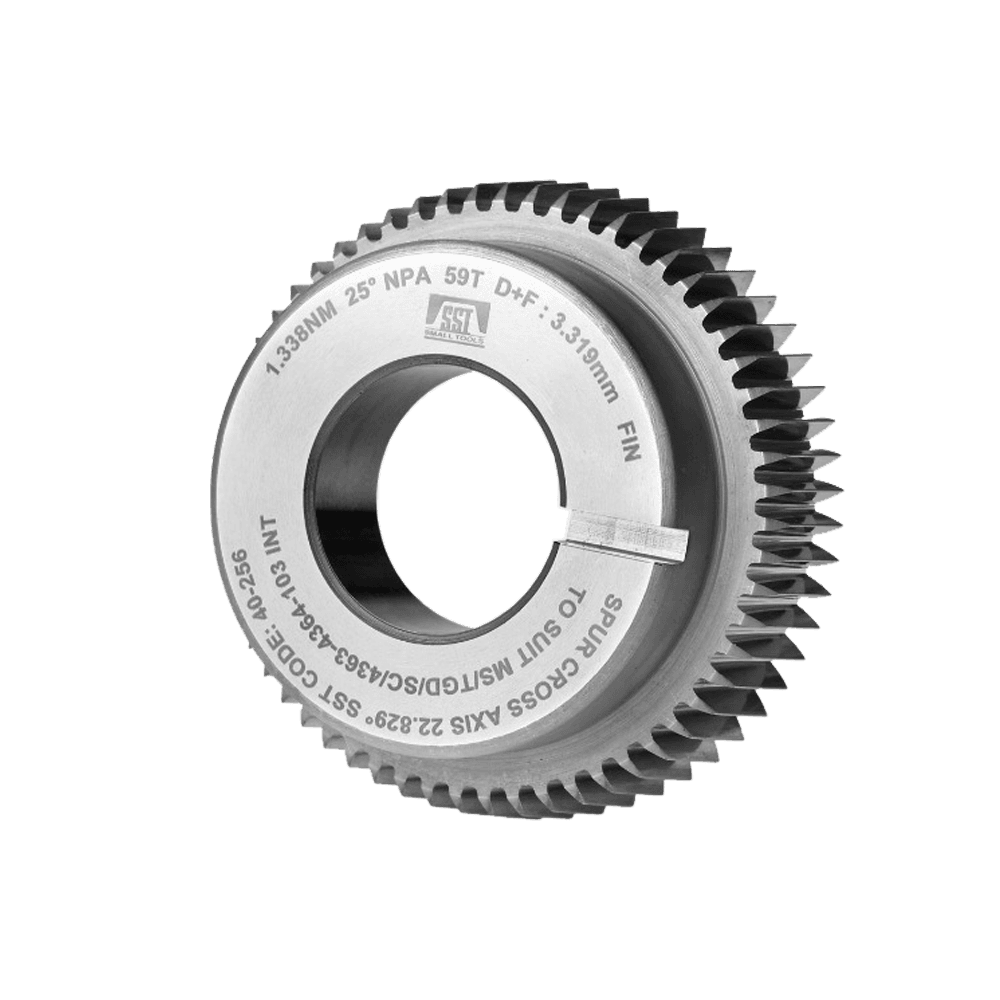

Material : ASP 2030, ASP 2052, ASP 2060

Module Range : 0.5 – 8 mm

Pressure Angle : 14.5°, 17.5°, 20°, 25°, Custom

Accuracy Class : Class ‘AA’, Class ‘A’

Helix Angle Range : 0° to ±45°.

Profile Types : Full-form, Tip Relief, Semi-Topping

Application Type : Internal & External Gear Cutting

Coatings Available : TiN, TiAlN, AlCrN

Clamping : Bores and shanks like shaper cutters; for specific tooling, please ask

Cycle time : 6x faster than shaping process

Gear Quality : DIN class 6 to 7

Surface roughness : Similar to shaving

Industries Served : Automotive, Aerospace, EV, Robotics, Gearboxes

Delivery Time : 4–6 weeks for standard; upto 8 weeks for custom tools

Module (DP) Range: 2 – 6 Mod. (DP 12 – 4)

Materials: PM High Speed Steels are available including: ASP 2052 / ASP 2030/ S390 / S290

Coatings: All types of PVD coatings are available including: Gold (TiN) / Futura Nano (TiAlN) / Alcrona (AlCrN)

Benefits of Power Skiving Cutters

Enhanced Efficiency: Skiving Cutters outperform shaper cutters and broaches in terms of speed and efficiency.

Versatility: Both externally and internally, they may create spur and helical gears.

Coolant-Free Machining: Skiving Cutters enable coolant-free machining, lowering expenses and having a smaller negative impact on the environment.

Short Cycle Time: Skiving tools make gear production faster with high cutting speeds, ensuring quick and efficient manufacturing.

High-Quality Gears: Skiving Cutters create high-quality gears with little surface roughness.

Suitable for Special Machines: These tools are compatible with multi-purpose CNC machining centers and specialized skiving machines.

Global Availability: S.S. Tools provides these Skiving Cutters for the global market, assuring accessibility to customers everywhere.

Benefits of Power Skiving Cutters

- Speed: Skiving cutters produce gears faster than shaping cutters, thus reducing time especially while achieving higher precision. Hence, power skiving becomes a fit for high-volume production where turn-around time is key.

- Flexibility: It can be applied to internal and external gears, eliminating the need for different application tools. Thus, tool management becomes easy, and the overall cost of production gets reduced.

- Surface Quality: Continuous cutting prevents excessive tool wear and enhances the finish, diminishing the need for further finishing processes with highly precise and long-lasting gears as finished products.

Features of Power Skiving Cutters

- Material & Coating: Power skiving cutters get made from cutting-edge materials and coatings that guarantee they are robust and will last. They are usually made of high-speed steel or carbide, well known for excellent wear resistance and prolonged tool life.

- Precision: A smooth tooth profile plus precision is guaranteed to make gears within close tolerances with power skiving cutters. Precision is the key demand for high-performance gears used in industries like automotive, aerospace, and industrial machinery.

- Customization: Customization of power skiving cutters according to the application requirement is another crucial manufacturing function. Whether for wise-pitch gears, hardened materials, or complex geometries, these power cutters meet different manufacturing requirements through customization.

Additional Must Notes

- Power skiving cutters get coupled with machines designed for skiving activities to ensure top performance. Suitable combinations of cutters and machines enhance efficiency and prolong tool life.

- Cutter specifications will differ from material to material; for high-hardness materials, carbide cutters are preferred, while high-speed steel ones are economically viable for softer metals.

- Any misalignment of the tool will affect the final quality of the gear. To achieve the intended accuracy, an accurate setup and calibration system should be devised with perfection.

FAQ's

Power skiving cutters are tools designed for power skiving, a superlative gear-manufacturing method combining elements of hobbing and shaping. These cutters ensure faster production times and enhanced gear quality.

Material coating, tooth geometry, and compatibility with the machining setup are crucial factors when selecting a power skiving cutter. The right cutter cuts effectively and prolongs tool life.

Frequent checking for wear, adequate lubrication, and proper storage conditions help attain maximum life for power skiving cutters. The dull or damaged cutters need immediate replacement to maintain cutting accuracy.

All operators should wear protective clothing and gear, secure tool alignment, and obey the machine’s instructions to prevent accidents. Well-maintained and appropriately established cutters reduce risk during operations.