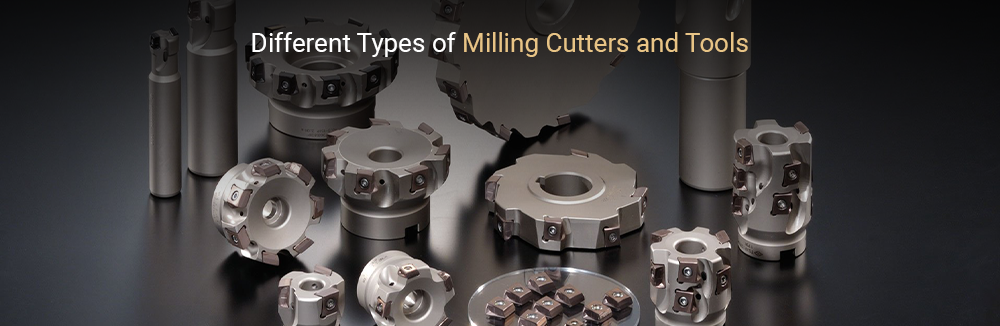

There are several kinds of machines that are utilized in the subtractive manufacturing technology along with computer numerical control-based systems so that consumers always have proper access to the best quality milling cutters as well as tools. The gear milling cutter is also very commonly utilized in the mining centers so that cutting procedures can be performed automatically and the process of creating the finished product is highly simplified. The whole concept is based upon higher levels of automation and lower needs of the workforce.

Most commonly, there are two types of cutters which are the end mill and the face mill. The basic difference between both of them is the end mill utilizes both the ends and all the sides of the cutter, and on the other hand, face milling is only utilized for the horizontal cutting.

Following are some of the bifurcations of such cutters:

End Mill: These kinds of tools are having a flat bottom and also round in shape. These kinds of tools are very much similar to drills because they can also cut axially. They also help to provide the benefits of lateral cutting.

Face milling: The face mills are unable to cut axially. Instead of this, the cutting edges are always very well located on all the sides of the cutting head, and the cutting-based teeth are also replaceable which the best benefits of this concept are.

Ball cutter: These kinds of cutters are also termed as the ball mills, and they have a hemispherical-shaped cutting-based tip. The main objective of these kinds of tools is to always and properly maintain a corner type of radius for the perpendicular faces.

Slab mil: The slab-based mills are not very much common in modern machining centers, and they are very well utilized with manual-based milling machines so that large surfaces can be done quickly. The slab milling is also known by the term of surface milling.

Side and face cutter: This is considered to be the predecessor of the end mill. These kinds of cutters also have teeth all around the circumference and on the sides, which make them very much functional and similar to the end mills. These kinds of tools have also gained a lot of popularity because of several kinds of innovations in the technologies.

Involute gear cutter: These kinds of tools are considered to be special cutting tools and are utilized to mill the involute gears. Many times there are several kinds of cutters that are available to produce these kinds of gears with a certain amount of the teeth.

Fly cutter: These kinds of tools also have the same functionality as the face mills. Such tools also consist of the central body that will help in holding to cutters very easily. These kinds of tools are utilized for high-quality cutting.

Hence, gear cutting tools manufacturers also help to provide high feed rates and shorter cutting times throughout the process which is the main reason such tools are very much necessary for all organizations in this field. So what are you waiting for? Look for the best manufacturers.

WhatsApp us