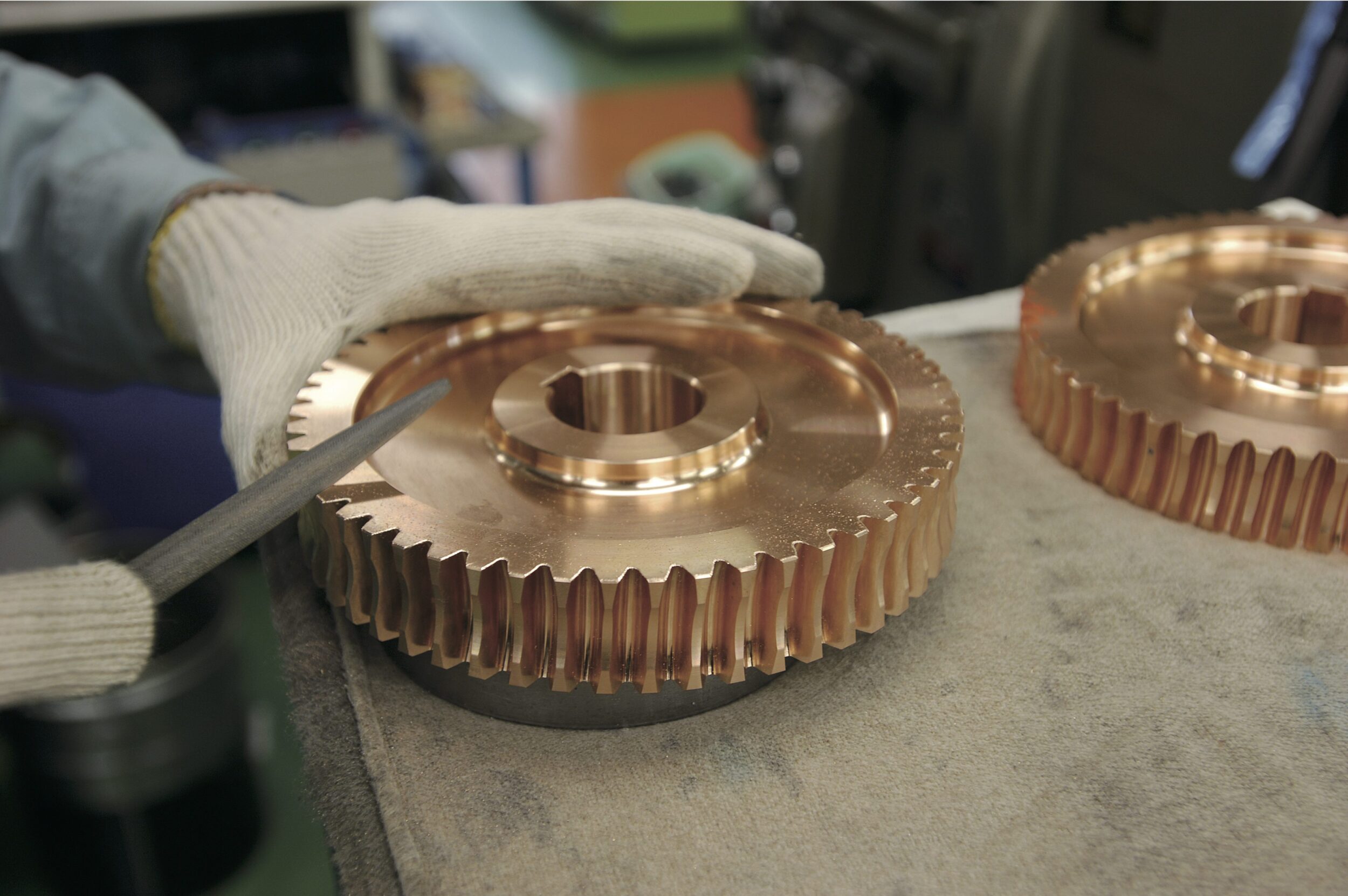

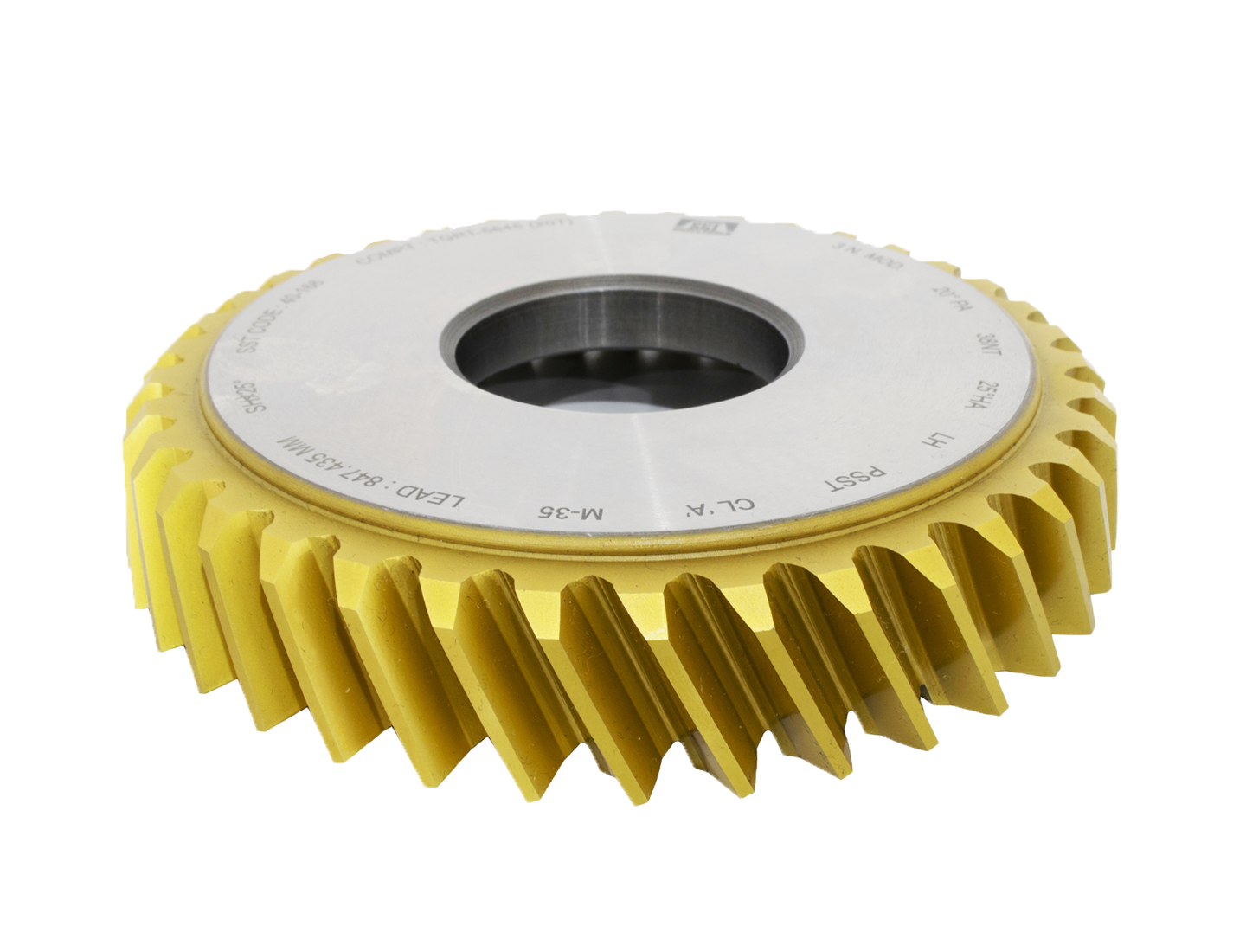

Gear shaving is a free-cutting gear finishing technique that involves removing tiny quantities of metal from the gear teeth’s working surfaces. Its goal is to fix index, helical angle, tooth profile, and eccentricity issues. The method can also increase tooth surface polish and decrease the risk of tooth end load concentrations in service by using crowned tooth shapes. Shaving allows for shape changes that minimise gear noise. Shaving cutters adjustments can also improve the weight bearing capability, safety factor, and service life of the gear.

- It’s important to distinguish between gear finishing (shaving) and gear cutting (roughing). They are fundamentally dissimilar. Any machine intended primarily for one task cannot be expected to perform both effectively and efficiently.

- Gear shaving is a reasonable solution to the errors that come with gear cutting. It works just as well as a control for these unpleasant heat-induced distortions.

- The gear shaving machine may also be reset to account for heat treatment lead changes.

Gear shaving removes tiny quantities of metal off the sides of gear teeth as a finishing process. Shaving improves the polish of tooth surfaces, reduces gear noise, and increases load bearing capacity by eliminating tooth end load concentration.

Benefits of gear shaving

Some of the benefits of the products according to the gear shaving cutter manufacturer:

It will always assure a better degree of accuracy

One of the best possible benefits connected with gear sharing processes is that it will always be based on a higher level of precision and accuracy, with the accuracy given by this specific cutter being highly dependent on the workpiece. When it comes to manufacturing, accuracy is crucial, and without it, production will not be able to reach the appropriate quality levels. If the cutter is employed, it will ensure that the gear is precisely crafted according to the designs and needs.

All costs will be kept to a minimum

The shaving cutter is also used for a variety of reasons, one of the most essential of which is the perfect aspect and cost-effectiveness of the entire production process. This method will always provide the best possible price for output ratios, lowering manufacturing costs. It will be ideal for industrial companies to be able to employ the equipment on greater scales. It will also try to keep prices as low as possible while achieving its objectives with the best-finished items available.

There will be more efficiency all of the time

The shaving cutter will also prove to be extremely beneficial in giving superior efficiency all the time when it comes to delivering the final touch to the equipment produced. The finishing formula will also affect the equipment, ensuring that instruments are properly employed and highly effective in terms of work performance.

It will be based on single sources

One of the most significant advantages of the entire process is that the finishing work will be performed by single sources.

Conclusion

As a result, anytime gears are created using gear shaving cutters, the performance will be substantially improved, ensuring that the best possible outcomes are achieved at all times.