For Any Enquiry, Call Us Now

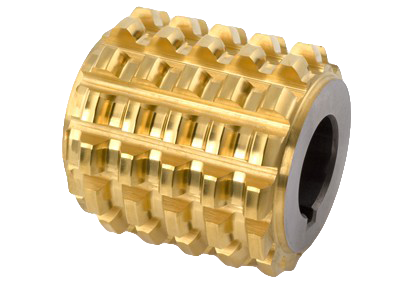

Straight Key Spline Hobs

These hobs have special curved tooth forms to produce straight key splines on shafts. Spline hobs produce exact tooth forms at given tooth depth. Various profile features including lugs and semi-topping can be incorporated on these hobs

Straight Key Spline Hobs

S.S. Tools is a pioneer and market leader for high accuracy Straight Key Spline Hobs.

These hobs have special curved tooth forms to produce straight key splines on shafts. Spline hobs produce exact tooth forms at given tooth depth. Various profile features including lugs and semi-topping can be incorporated on these hobs.

Parallel Key Spline Hobs, the utility-driven cutting tools, stand relentlessly at the forefront of gear manufacturing because of their specialized features. Made from high-speed steel or tungsten carbide, these hobs have curved teeth to match the profile of the desired splines on shafts. It delivers precision because when the hob rotates and is fed into the workpiece, it cuts away the material as per the desired splines.

The Precision Mastery And Other Benefits of Parallel Key Spline Hobs For Gear

Hobs can cut splines much faster than other spline-cutting methods, such as milling and broaching. Their remarkable adaptability offers an array of options while designing profile features such as semi-topping. Getting these customizable tools engineered by an adept maker will surely deliver speed and personalization to your output.

Suitable for versatile industrial requirementsIndustries like medical, aerospace, defense, agriculture, robotics, and more rely heavily on the precision of gears, possible only through mindfully and skillfully produced gear hobs. So, when precision becomes a non-compromising factor in any industry, Parallel Key Spline Hobs are perfect because of their curved tooth forms for a flawless fit on shafts. Their ability to cut different spline sizes and shapes will help meet the varying industrial standards.

Great for consistent production efficiencyTo ensure a continuous and efficient production rate, it is essential that the manufacturing process is carried out without pauses and delays. Using these hobs will help you optimize the entire procedure because of their ability to produce accurate results repeatedly. Its hardwearing material minimizes the risks of machinery failure. Thus, it will expedite production timelines, while promising overall cost-effectiveness with tight tolerances. If you are looking for tools to help you engineer customized profile features of the shafts with the utmost exactness, look no further than the Parallel Key Spline Hobs.