Industries are functioning continuously, which serves many fields with the necessary equipment to operate efficiently. Wherever there is machinery, the need for fully functioning gear comes up. And every gear manufacturing industry understands how crucial the tool is for running the machines smoothly.

Manufacturing the best gear and supplying the production industries takes in several stages. It also considers the material quality, gear profile and quality of shaving. Achieving all these is essential to ensure the outcome is perfect and clients are satisfied. Deploying gear shaving cutters makes sense in the gear manufacturing process, as most industries will feel its advantages.

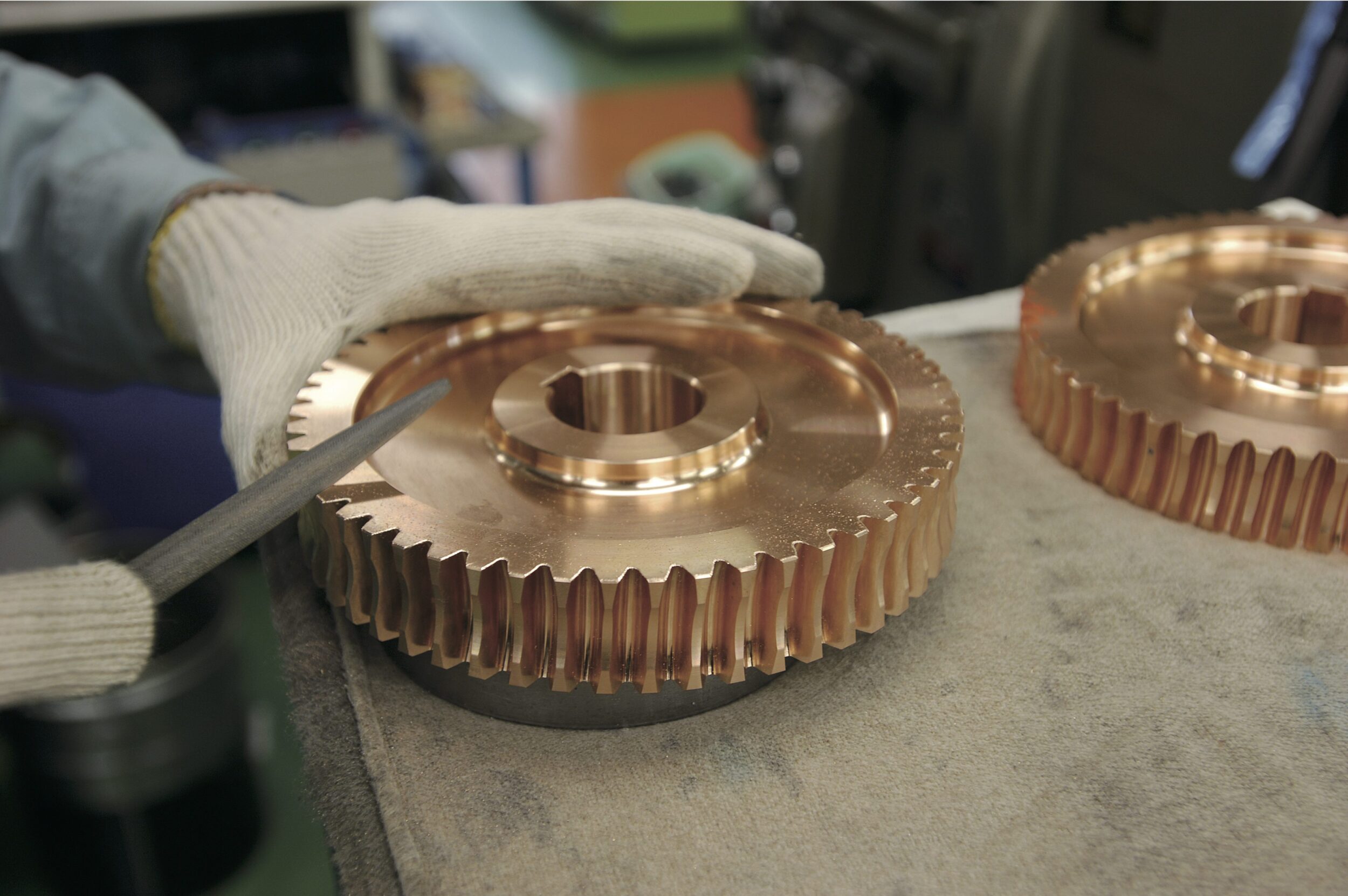

The process of gear shaving

The gear teeth have working surfaces that need proper tuning to remove excess material and result in the best product. With gear shaving, the removal of this material becomes smooth. The areas of the gears where a gear shaving cutter can help are index, eccentricity, tooth profile and helical angle. The tooth surface finish must be improved, for which the shaving cutter can be used.

Without a proper gear shaving process, when using the gears, it could result in gear noise that hampers overall machinery operations. The service life of gears is boosted drastically by incorporating gear shaving cutters into its manufacturing process, which also increases the load-carrying capacity with more safety ensured. The gear-shaving cutter tool ensures the outcome is the best that can be employed for shaving huge gear quantities.

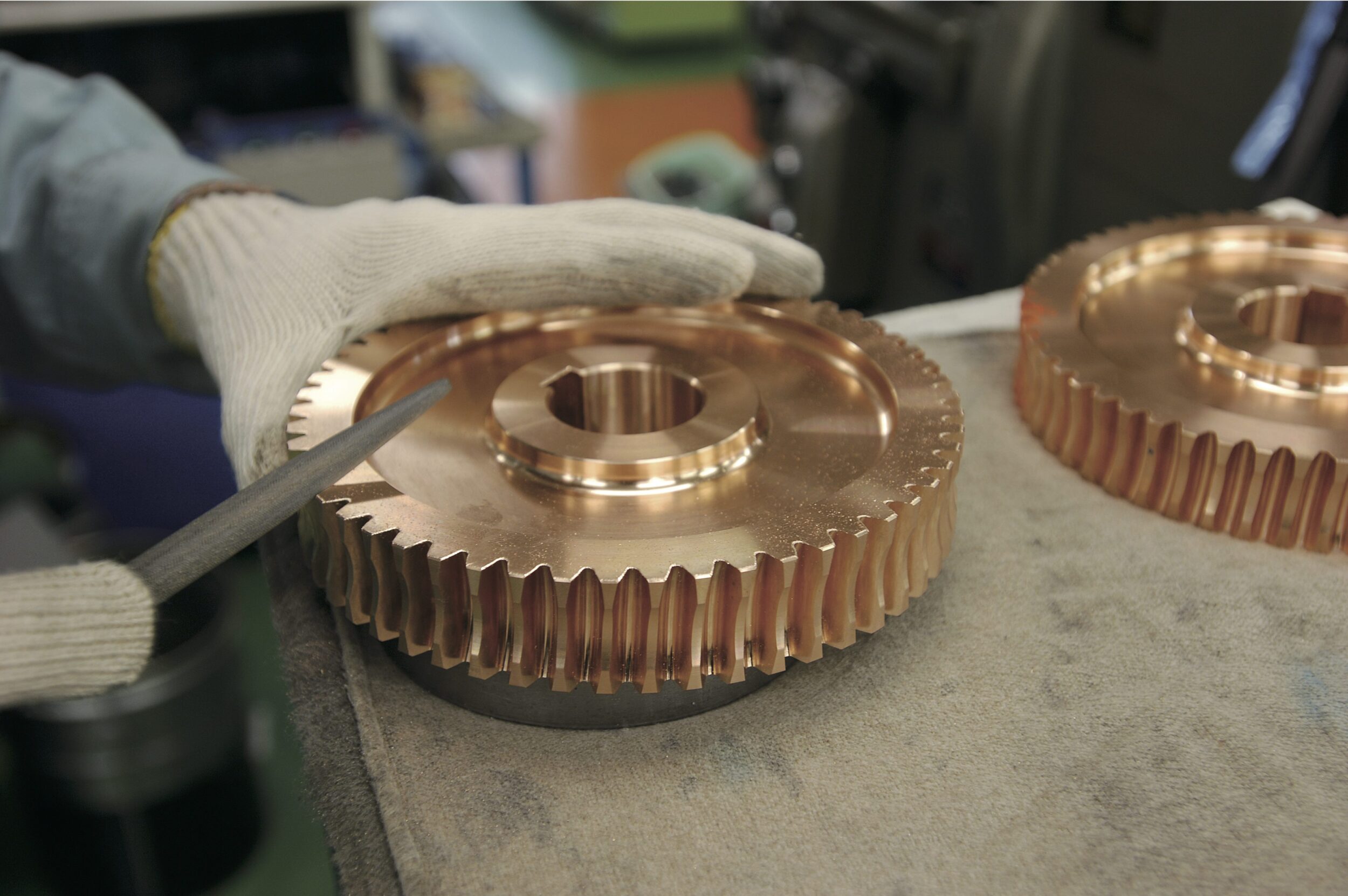

Improved gear accuracy

During the gear manufacturing process, it is difficult to determine the exactness of the gears and using gear shaving, attaining the same is feasible. The requirements of an industry would be something to achieve in the manufacturing process that the gear shaving procedure will ensure to the maximum. The highest accuracy is a guarantee when deploying this process into gear manufacturing that finalises the outcome.

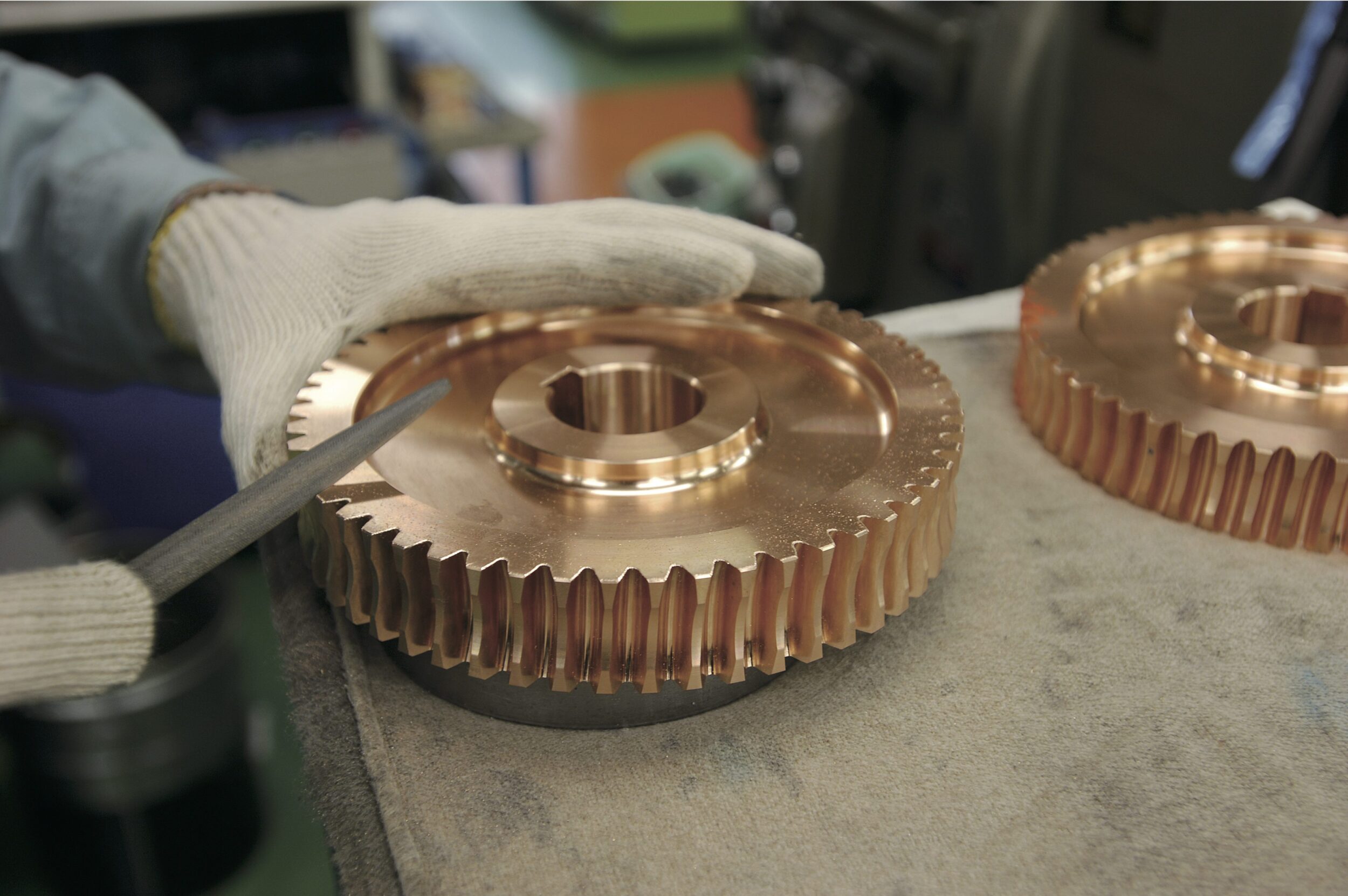

Cost-effective solution

In achieving accuracy for any manufacturing process, cost-effectiveness is the key to profitable growth. Using the gear shaving cutter offers this benefit, and the gears will be of the best quality affordably. Drastically, the cost of production is brought down, which bolsters the business to run efficiently and manufacture more number of gears for their clients. Utilise this opportunity and grab your shaving cutter from the market to start shaving the gears.

It doesn’t require further enhancements!

With a gear-shaving cutter, there is no need to think about the finishing touch for the gears. The final product from the tool would be so perfect that it can be rolled into the market for sale. It is a distinguishing factor that needs to be noted when considering employing a gear-shaving process with the cutter. Overall performance spikes help the gear manufacturing industry to experience lucrative and efficient business with their clients.

It is the best finishing tool to go behind and buy first for addressing the gear quality issues. Your gears will have the best grade in the market without any doubt. Make a responsible decision to use a gear-shaving cutter in gear production for promising benefits.

WhatsApp us