The gear cutting tools manufacturers in India always aim to provide the best quality tools and equipment which are utilized throughout the gear cutting procedures. Whenever these kinds of processes have been undertaken, and haircutting is done, there is a specific type of material which are utilized in their production. The gear cutting machine is also used in several kinds of tasks throughout the process. Whenever there is a need for any kind of gear, the gear cutting machines are very well utilized to produce the most suitable cuts. The gear cutting processes are very well able to provide gears of different shapes and sizes so that efficiency throughout the process can be increased.

Following are some of the important bifurcations of Gear cutting procedures:

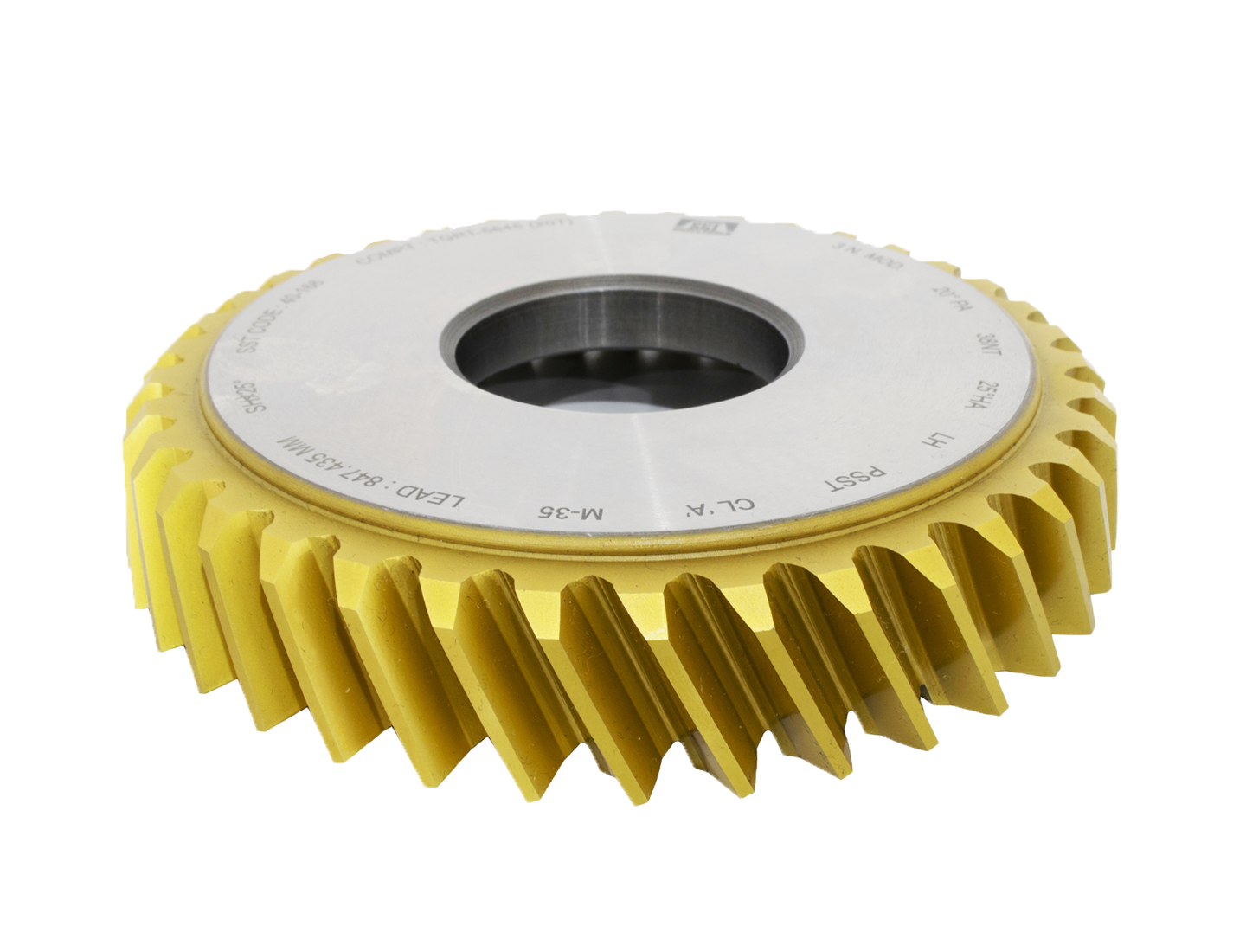

-Hobbing process: the hob can be very well utilized in cutting the teeth of the gear, and this particular process is used in shortening the gears. The hob must be able to complete one particular revolution so that teeth of any kind of gear are built. These kinds of processes are used with the help of the best quality products so that helical and spur gears can be produced. The hobbingis considered to be the best possible technique among all the techniques available in this industry.

-Broaching technique: this particular technique is used in dent shaping the gears. This particular method is very much expensive, and it has to be very well utilized at the time of fabricating a large number of gears. This is the procedure in which teeth can be cut inside specifically. Under this procedure, Alex is available on the Y-axis along with the Rotary surface. Around the Y-axis there will be a deep cut, and there will be indexed chef cutting by the gear cutting machine.

-Grinding procedure: the grinding procedure is utilized in the manufacturing of helical gear on the manual machine. The helical gear is considered to be the true indexing fixture which has to rotate in a specific ratio. These kinds of gears are produced with the help of rack shaped cutters.

-Shaping processes: These kinds of processes help in trimming the gears and are considered to be one of the smoothest as well as the oldest method of slicing the gears. In this particular process, the gear blank is mounted on the shaper with the help of a tool which is like a tooth, and it has to be cut for the internal spines. The gear cutting machine is also used with the help of pinion shaped cutters so that processes can be completed easily.

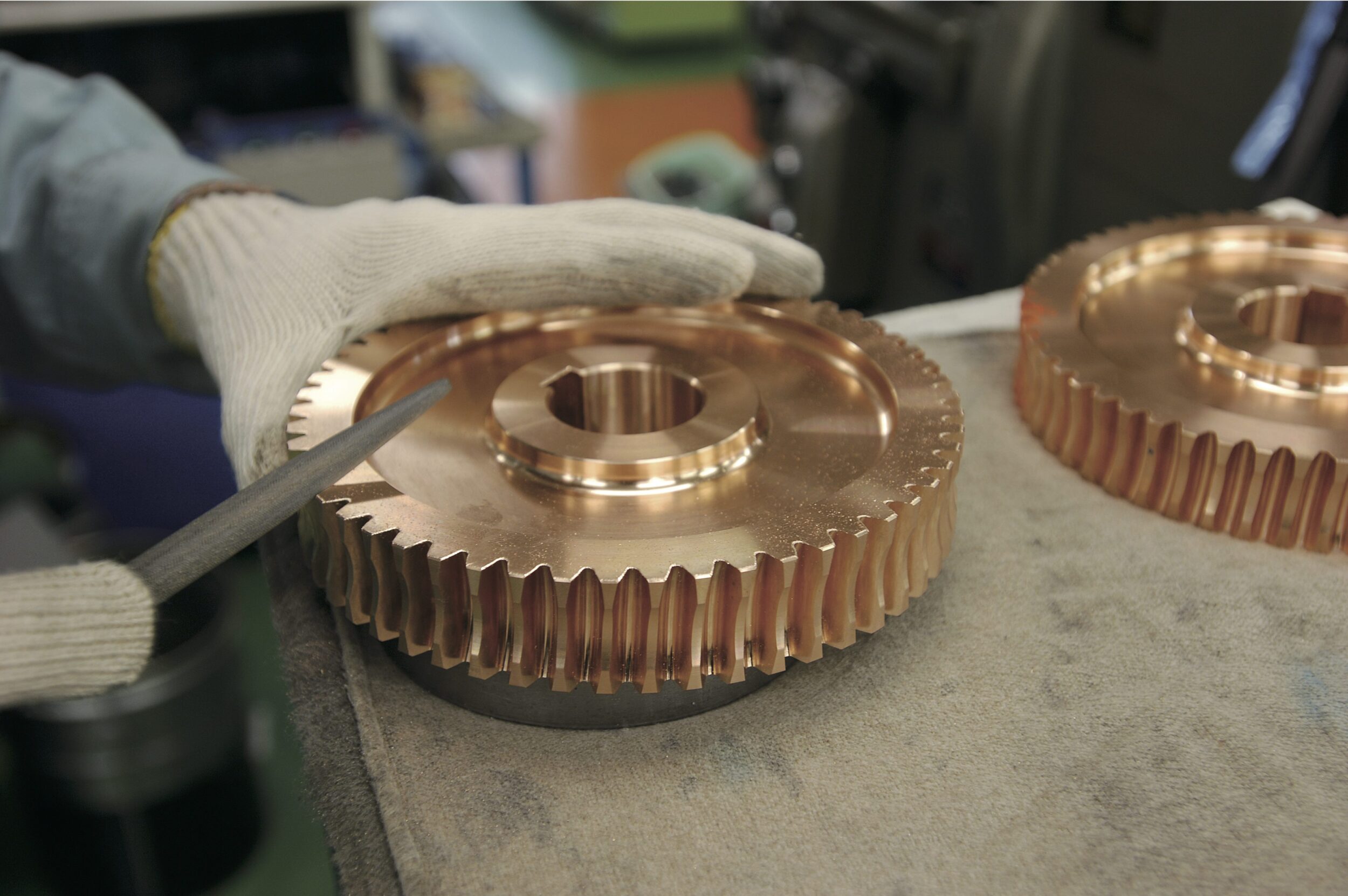

The finishing procedure: This particular point includes the processes of gear cutting finishing, brushing, lapping, shaving, and several other things so that gear cutting is efficiently done.

These kinds of gear cutting procedures which range from broaching to finishing are completed with the help of the best quality gear cutting machines. The gear milling cutter is also utilized throughout the process to enhance the efficiency element and make sure that the best quality gears are produced. Ultimately the whole concept is directly linked with goodwill and proficiency of the companies as they make sure that customers are highly satisfied all the time.