Precision is what modern engineering means by “performance.” Accurate gears are needed for every machine to move power smoothly. Noise, economy, and service life can all be affected by even small mistakes in gear design. This is why it is so important to have a precise gear shaving cutter manufacturer in the business world.

Gear-cutting tools are very important for finishing gears with high precision. After hobbing or shaping, they smooth out the tooth profiles. This process makes it easier to control dimensions and surface finish.

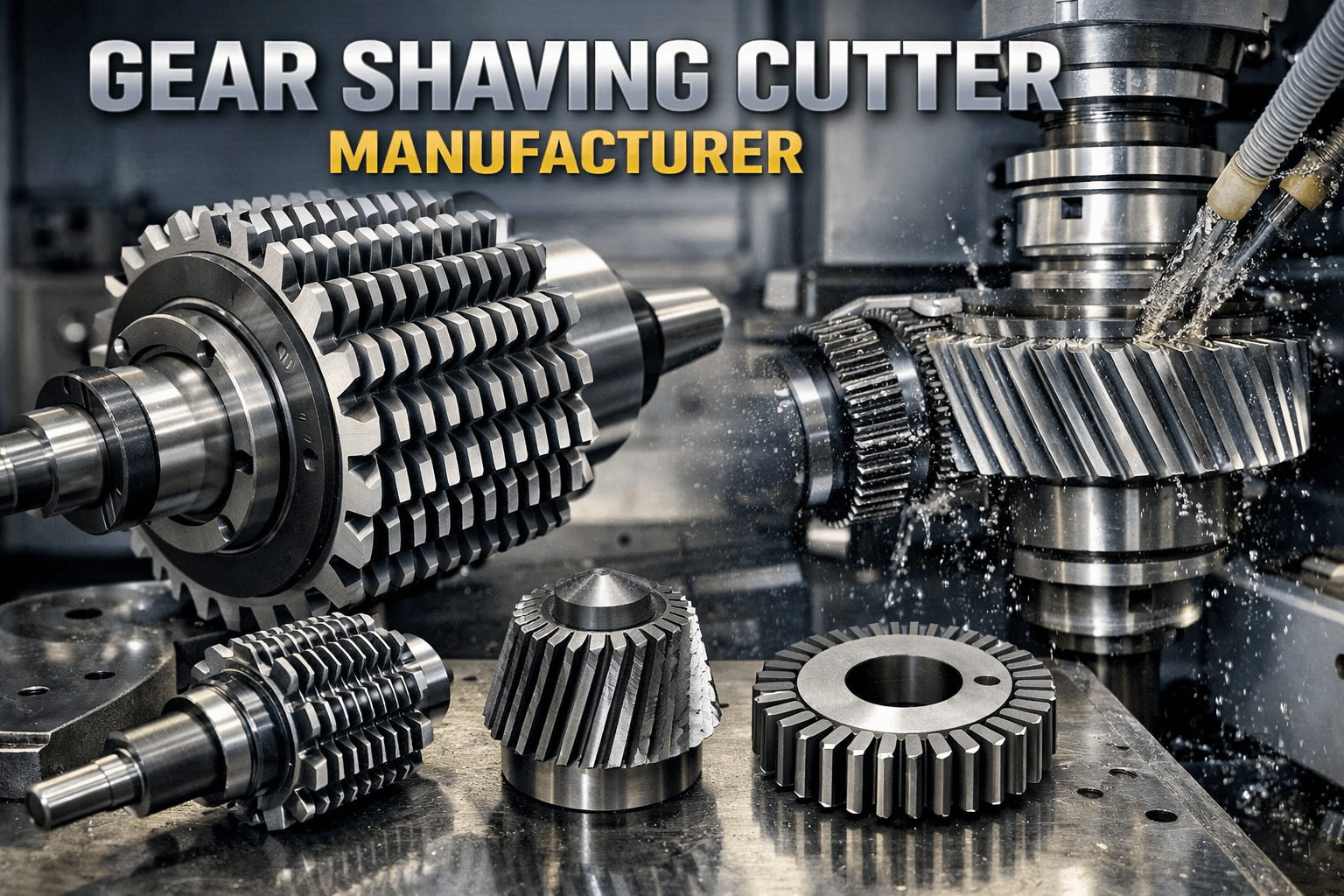

How to Use Gear Shaving Cutters?

Gear shaving cutters are finishing tools that are used to produce a large number of gears. They remove small amounts of metal from the gear teeth. This adjustment process improves accuracy and load distribution. It also improves the quality of gear meshing.

The teeth on these cutters are all sharp and uniform in size. Each tooth has a very precise shape. This ensures that the cutting action is consistent over the entire gear surface. The result is smooth operation and reduced wear.

Why Is Gear Shaving Still Important?

Even though grinding has advanced significantly, shaving is still widely used. It offers a high level of output at lower cost. For many applications, shaving gears is faster than grinding them. It also delivers very good surface quality.

Shaving is used to manufacture gears for automobiles, factories, and transmissions. Tight tolerances can be achieved with this method. It also performs well in high-volume production environments. Because of these benefits, shaving remains popular worldwide.

The Role of a Specialized Manufacturer

Every step of the process is highly precise for skilled gear shaving cutter suppliers. Tool manufacturing requires deep technical knowledge. Shape, material selection, and heat treatment are all critical. Each decision affects cutting performance and tool life.

The cutter body and teeth are formed using advanced CNC machines. Every stage is followed by strict inspection. Quality checks ensure proper surface finish and geometry. This methodical approach produces tools that perform reliably under demanding conditions.

The Materials That Determine Performance

Powder metallurgy alloys and high-speed steel are commonly used. These materials are strong and highly wear-resistant. Proper heat treatment increases hardness. Coatings can also be applied to extend tool life.

Material selection depends on application requirements. In high-volume production, extended tool life may be required. For precision applications, cutting edges must remain stable. Skilled manufacturers carefully balance these factors.

How Important Is Tool Geometry?

Gear quality is directly influenced by cutter geometry. Tooth angle, pitch, and spacing must be precise. Any deviation can affect gear noise and strength. Accurate geometry ensures uniform material removal.

Modern design tools help optimize geometry. Simulations predict cutting behavior before manufacturing. This reduces trial time and improves accuracy. It also ensures consistent results across different gear types.

Global Demand for Precision Tools

Precision gear cutting tools are used across industries worldwide. Heavy machinery, automotive, and aerospace are major users. Renewable energy equipment also requires high-quality gears, with wind turbines being a prime example.

Precision tools support both safety and efficiency. They reduce waste and downtime, helping industries remain competitive and innovative.

Meeting Global Quality Standards

Global markets demand strict compliance with standards. Quality control follows ISO and DIN specifications. Testing and consistent documentation are essential. Buyers need assurance of reliability.

Suppliers that meet these standards gain trust and wider market access. Certification demonstrates commitment to excellence. Customers feel confident in long-term performance.

Strength and Dependability of the Supply Chain

On-time delivery is as important as product quality. Logistics must be well managed by both gear shaving cutter manufacturers and distributors. Reliable supply chains reduce production delays, which is critical for large operations.

Strong relationships with gear shaving cutter suppliers ensure continuity. These suppliers provide product availability, technical support, and customization. End users benefit from this collaborative approach.

Adapting to Industry Needs

Every gear application is unique. Different tools are required for different jobs. Custom solutions handle unique profiles and materials, improving cutting speed and durability.

Manufacturers work closely with customers to understand requirements. Development is guided by detailed drawings and samples. Performance is validated through testing before full-scale production. Customization enhances accuracy and value.

New Technologies in Manufacturing

Digital tools have transformed cutter manufacturing. CNC machining ensures consistent precision. Automation reduces human error. Advanced inspection systems verify every detail.

Data-driven manufacturing improves consistency. Feedback loops enhance design and process control. Over time, this results in better tools. Technology continues to raise industry standards.

Technical Service and After-Sales Support

Quality service extends beyond product delivery. Technical support helps maximize cutter performance. Assistance with setup and maintenance improves efficiency and prevents premature wear or failure.

Operators benefit from training and clear documentation. Proper guidance ensures correct usage and optimal tool performance.

How to Choose the Right Supplier

Selecting the right supplier requires careful planning. Experience, quality control, and technical support are essential. A reliable gear shaving cutter manufacturer is transparent and knowledgeable, ensuring consistent results.

Buyers should evaluate manufacturing processes and testing methods. Global reach is important for international operations. Dependable gear shaving cutter suppliers offer both quality and cost efficiency, supporting long-term growth.

Conclusion

Modern industries rely on precision gear cutting tools. Gear shaving cutters ensure accuracy, durability, and smooth operation. Skilled manufacturing combined with dependable global supply makes a significant difference. Choosing the right partner guarantees quality, efficiency, and long-term success.

FAQs

Who Is the Best Gear Shaving Cutter Manufacturer in India?

A reliable gear shaving cutter manufacturer in India should offer technical expertise, CNC capabilities, strict quality control, ISO/DIN compliance, and a proven track record in automotive, industrial, and heavy equipment sectors.

How to Choose Reliable Gear Shaving Cutter Suppliers?

Choosing dependable gear shaving cutter suppliers involves evaluating product quality, manufacturing capability, and the availability of technical support.

What Is the Cost of Gear Shaving Cutters for Industrial Use?

Industrial gear shaving cutter pricing depends on multiple factors, including design complexity, materials, and testing requirements.

Do You Offer Custom Gear Shaving Cutter Manufacturing?

Yes, we offer custom gear shaving cutter manufacturing