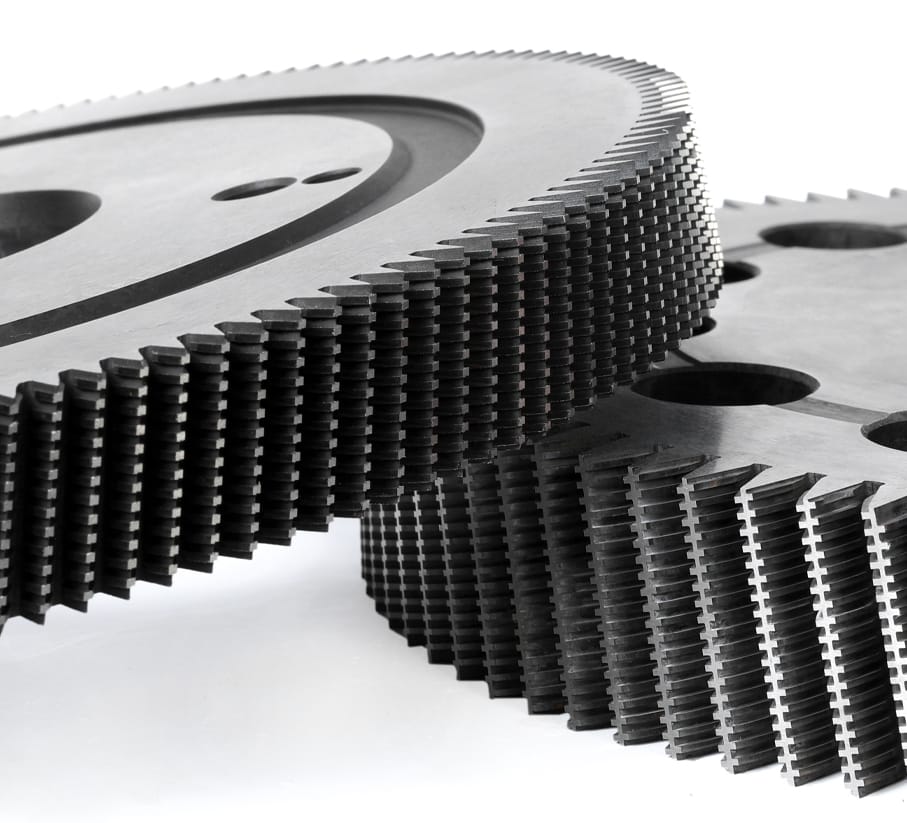

Gear Shaving Cutters

S.S. Tools is a pioneer and market leader for high accuracy Gear Shaving Cutters.

The company produces a wide range of shaving cutters such as conventional, diagonal, underpass & plunge. Shaving cutters are generally supplied with standard true involute profile, however special modified profiles can be offered to generate tip/root relief, ‘K’ profile, lead crowning, etc. as per customer’s requirement. Being a single source for various pre-shaved tools-hobs & shaping cutters, design parameters of shaving cutters are optimized to achieve better contact and desired form diameters in gears. All the manufacturing activities including designing, producing and inspection are intramural.

With the vast experience in this field and latest software solutions, S.S. Tools has perfected the tool design and optimization formula which makes the tooling extremely precise. Additionally, the company also offers re-sharpening of shaving cutters of any reputed make.

Module Range : 1 – 8 mm

Diameter Range : 70 – 300mm

Maximum Width : 60mm

Bores : 63.50 and 100mm

Maximum Helix Angle : 40 deg RH & LH

Type : Conventional, diagonal, underpass, plunge

Profiles : Standard, Involute modifications, lead crowning etc

Material : Conventional / PM High Speed Steels are available including: M2 / M3/ ASP 2023

Application : Finishing of external spur/helical gears to improve surface finish and precision

Lead Time (New) : 4–6 weeks

Lead Time (Resharpening) : 3 days

Module (DP) Range: 1.25 – 8 Mod. (DP 20 – 3)

Diameter Range: 70 – 250 mm

Maximum Width: 60 mm

Materials: Conventional / PM High Speed Steels are available including: M2 / M3/ ASP 2023

Benefits of Gear Shaving Cutters

Precision: S.S. Tools, a reputable innovator in highly accurate gear shaving cutters, guarantees accurate gear fabrication.

Variety: They provide a large selection of shaving cutters, including choices for customization, to fulfill the demands of various industries.

Quality: S.S. Tools upholds high product quality through in-house production, design optimization, and contemporary software solutions.

Global Reach: Their products are exported to foreign markets, making premium gear tools available.

Customization: Shaving cutters can be customized by S.S. Tools to meet the needs of particular industries without sacrificing quality.

Expertise: Years of experience have allowed for precision tool design and adjustment.

Re-Sharpening Services: They provide re-sharpening services to prolong the life of various shaving cutter brands.

Industry Compatibility: With a variety of shaving cutter types and the guidance of an experienced staff, S.S. Tools satisfies a range of industry requirements.

Precision Perfected: An In-Depth Look at Gear Shaving Cutters

Achieving perfect surfaces for gears is essential in gear manufacturing. And something that plays a critical role in refining gear tooth surfaces to an advanced state is gear shaving cutters. This article explains the advantages of gear-shaving cutters that impact the qualities of the manufactured gears:

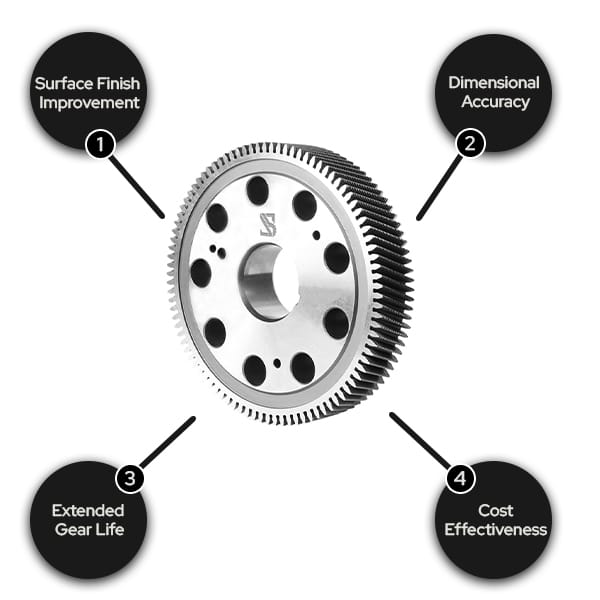

Benefits of Gear Shaving Cutters

A Gear shaving produces several advantages that result in improved quality and efficiency in gear manufacturing:

- Surface Finish Improvement: They significantly improve surface finish quality by chipping away very minute bits of gear teeth—a key factor in enhancing operation smoothness and reducing noise in their system.

- Dimensional Accuracy: Corrects minor deviations that may occur in the gear tooth profiles and ensures precision in dimensions and alignment – crucial for high-performance applications.

- Extended Gear Life: It reduces wear and tear by fine-tuning gear to perfect finishes and close tolerances. This results in a longer life span of gears.

- Cost-Effectiveness: Including gear shaving in the production could easily minimize the need for considerably more expensive grinding operation without losing the quality intended for it.

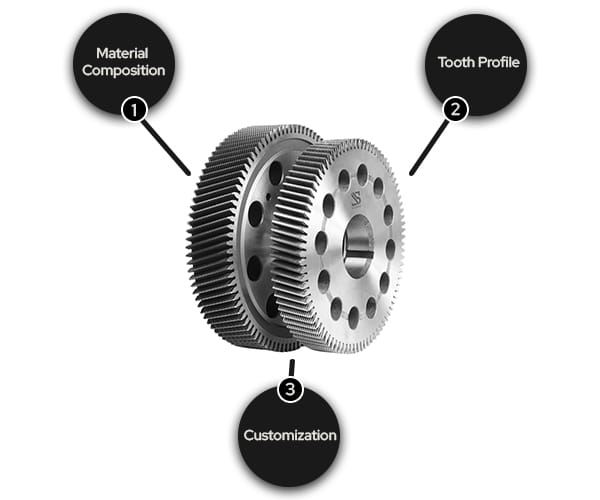

Features of Gear Shaving Cutters

- Material Composition: Gear shaving cutters are made of high-speed steel (HSS) for durability and resistance to wear.

- Tooth Profile: Besides precision tooth profiles, gear-shaving cutters are structured for specific profiles and gears to allot effective chip removal along with refined surfaces.

- Customization: Customization options are offered by manufacturers to get variations on module, pressure angle, and helix angle that fit a very expansive diversity of gear specifications.

Additional Must Notes

- Ensure that the gear shaving cutter is compatible with the current gear shaving machine by considering mounting dimensions, machine capacity, and synchronization requirements.

- Optimal cutting speeds, feed rates, and types of fluids are key elements in achieving the desired results and prolonging the tool’s life.

- Regular sharpening of shaving cutters is essential to ensure the life of cutting tools and avoid defects in gear teeth.

- Using skilled operators who understand the gear-shaving process contributes to superior gear quality.

FAQ's

A gear-shaving cutter is a precision tool that removes a thin material layer from the tooth surface. It provides an improved surface finish and corrects minor profile errors, resulting in gears that run quieter and more smoothly.

One should periodically inspect wear, clean away debris and timely re-sharpen to preserve the cutter’s edge. It also requires proper storage to keep any damage at bay, and routinely check for proper coating and functioning.

Gear hobs cut gear teeth for manufacturing of gears. It defines the basic profile of the tooth. On the contrary, gear-shaving cutters post-hobbing are used to improve the surface of teeth against post-hobbing cutter limits, correct minute inaccuracies, and improve overall gear quality.

Operators should wear safety glasses and gloves to prevent metal shavings and edges from coming into contact with them. Additionally, sticking to the manufacturer’s instructions on operating standards and maintenance helps prevent accidents and ensure safe utilization.