The role of gears is essential in the world of mechanical engineering and manufacturing since gears transfer power and motion efficiently without wastage. Behind every finely tuned gear lies the cutting tool with which the gear could be formed—the gear shaper cutter.

What Are Gear Shaper Cutters?

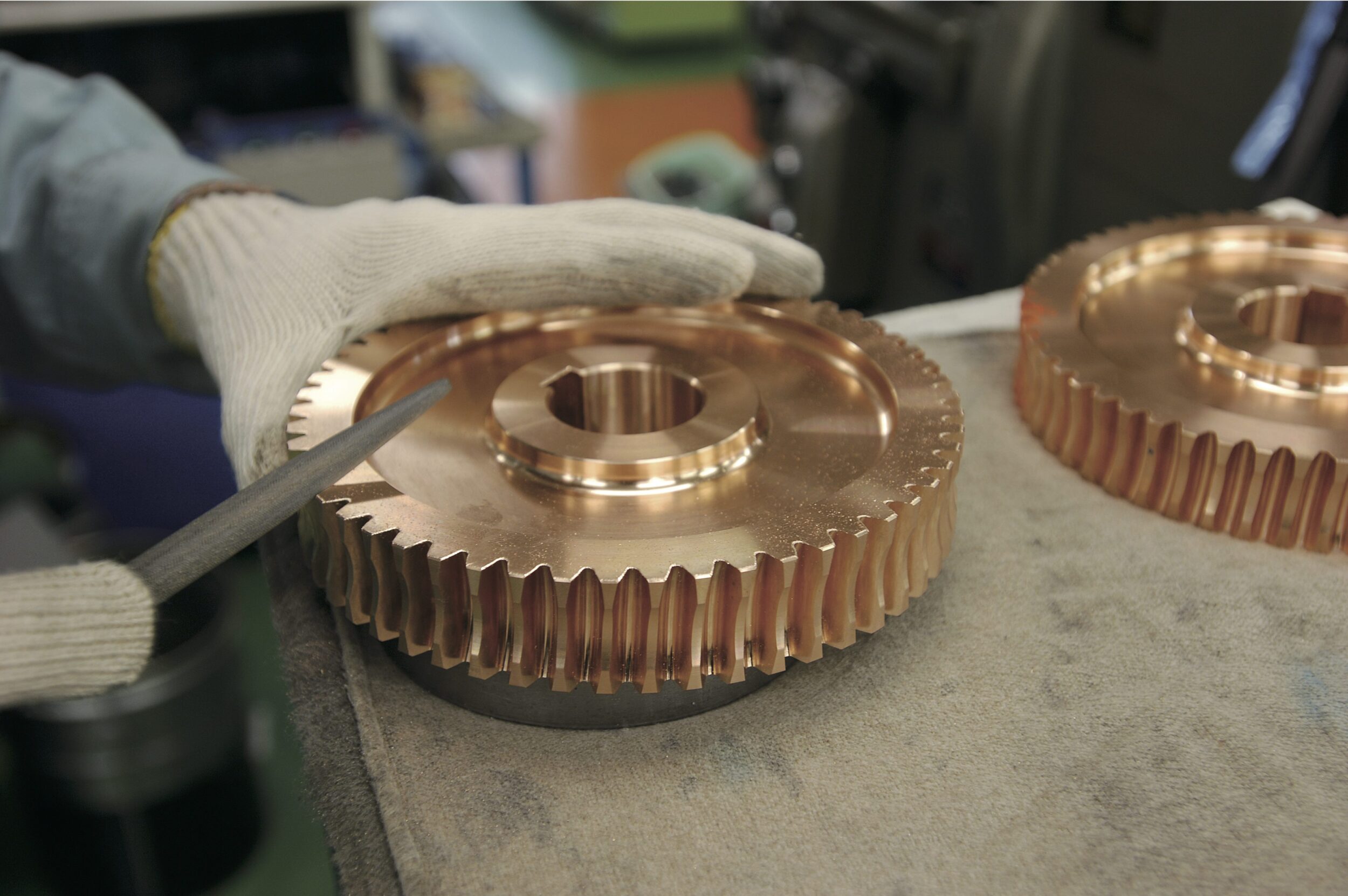

Gear shaper cutters are specialized tools for cutting internal or external gear teeth. Unlike milling and hobbing, the cutting action consists of a vertical stroke by the tool of the workpiece, similar to a piston, during which these elements get timed together. This gives an operation advantage in shaping very complex or difficult gear geometries challenging with other operations.

These are predominantly HSS or carbide-bonded, depending on the machine-processed application and material. The configuration of a gear shaper cutter is the reverse shape of the gear it will produce, and it demands extreme accuracy in engineering and construction.

Types of Gear Shaper Cutters

Gear shaper cutters differ according to various forms of gears that exist in the industries. The disk-type cutters are usually for external gears, hub-type for internal gears, and helical gear shaper cutters for more complex geometries. These tools can be standard or tailored type, relying on how specific or complex and accurate the requirements are for the gear.

There is also a difference in that semi-topping and topping cutters modify the top part of the gear tooth to form a better fit and minimize interference. The type of cutter is mostly dependent on the module, pressure angle, or straight or helical gear.

Where Precision Matters Most

The gear shaping most utilized in the industries is for the precision and reliability requirements, such as automotive, aerospace, robotics, and heavy machinery. It is because even a minute inaccuracy causes either more wear and reduced performance or, worse, catastrophic failure. Hence, gear shaper cutters must keep very close tolerances, profiles repeated regularly, and be durable against wear even after thousands of cycles.

The Evolving Future of Gear Shaping

With the development of automated and controlled gear-shaping machines, the gear-shaping process has entered a new level of efficiency and repeatability. High-performance cutters, capable of withstanding high speeds and more robust applications, are now in demand.

The development of cutter design, cutter materials, and cutter coatings will continue to enhance in keeping with industry demands for tighter tolerances, faster cycles, and reduced costs. Gear shaper cutters are an integral part of this chain that leads to gears running the modern world across industries.

Conclusion

Gear shaper cutters are the heart of gear manufacturing, merging engineering and material science to give precision and reliability in building sound machines across demanding industries. Often, they craft very complicated gears with tolerance, making the machine perform better in smoothness, longer duration, and efficiency. As the industries grow and evolve, these tools remain foundational, shaping the future one gear at a time.

FAQs

1. How do gear shaper cutters differ from hobbing and milling tools?

Gear shaper cutters cut gear teeth one at a time using a reciprocating motion, perfect for internal and small-tooth-count gears, whereas hobbing uses a continuously rotating hob that cuts multiple teeth simultaneously for fast and high-volume production of external gears. And milling cutters cut each tooth individually on a milling machine in a start-stop process, suitable for smaller batches or large custom gears with slower production speeds.

2. What materials are used for gear shaper cutters?

Mostly High-Speed Steel (HSS) or carbide is used which is chosen based on gear material and machine application.

3. What types of gear shaper cutters exist?

Disk-type for external gears, hub-type for internal gears, helical cutters for complex shapes, and semi-topping/topping for tooth modifications.

4. Why is precision critical in gear shaper cutting?

It is critical because even minor inaccuracies cause wear, reduced performance, or potential failure in automotive, aerospace, robotics, and heavy machinery applications.

5. How are modern gear shaper cutters evolving?

Through advanced cutter designs, improved materials, specialized coatings, and compatibility with automated, high-speed, and high-precision gear-shaping machines.