Gear Hobs: All You Should Know This Important Tool Used in Gear Production

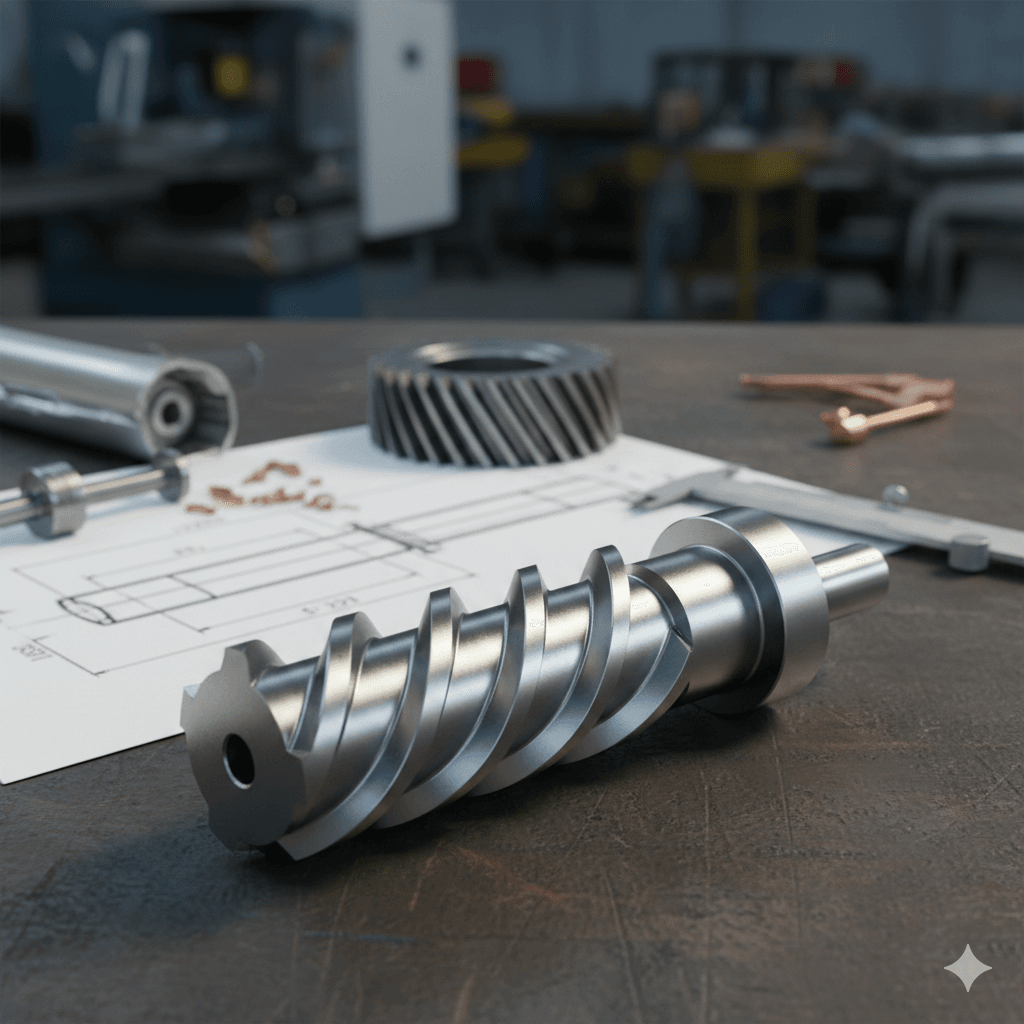

Gear hobs are simple but vital tools used in the gear manufacturing process. They are used to form gear teeth with incredible accuracy. Gear hobs play a vital role in gear manufacturing. They are used in almost all types of gear manufacturing machines. It would be harder and slower to manufacture good, quality gears without […]

Gear Hobs: All You Should Know This Important Tool Used in Gear Production Read More »