Precision in Motion: Understanding the Role of Gear Shaper Cutters

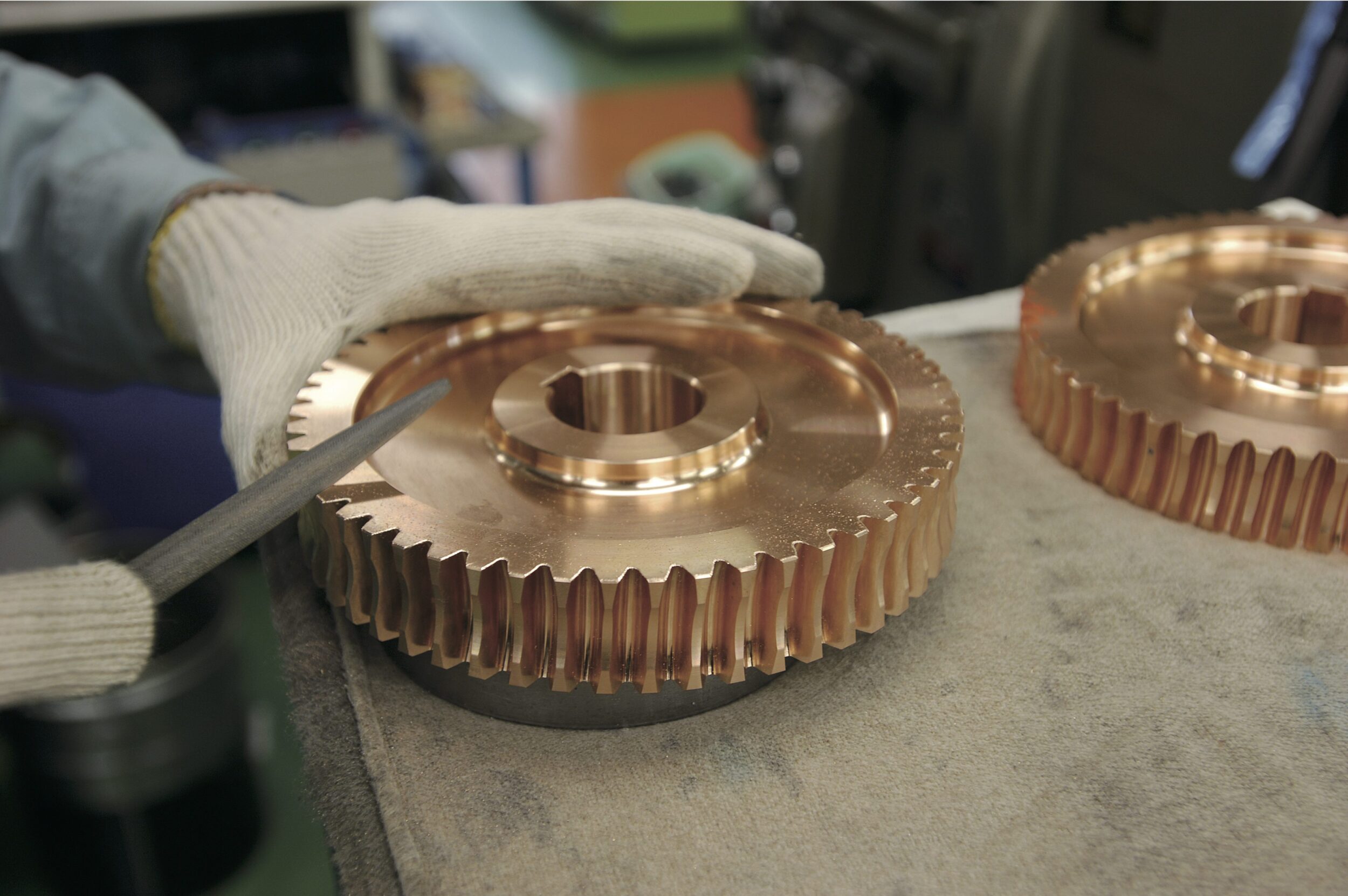

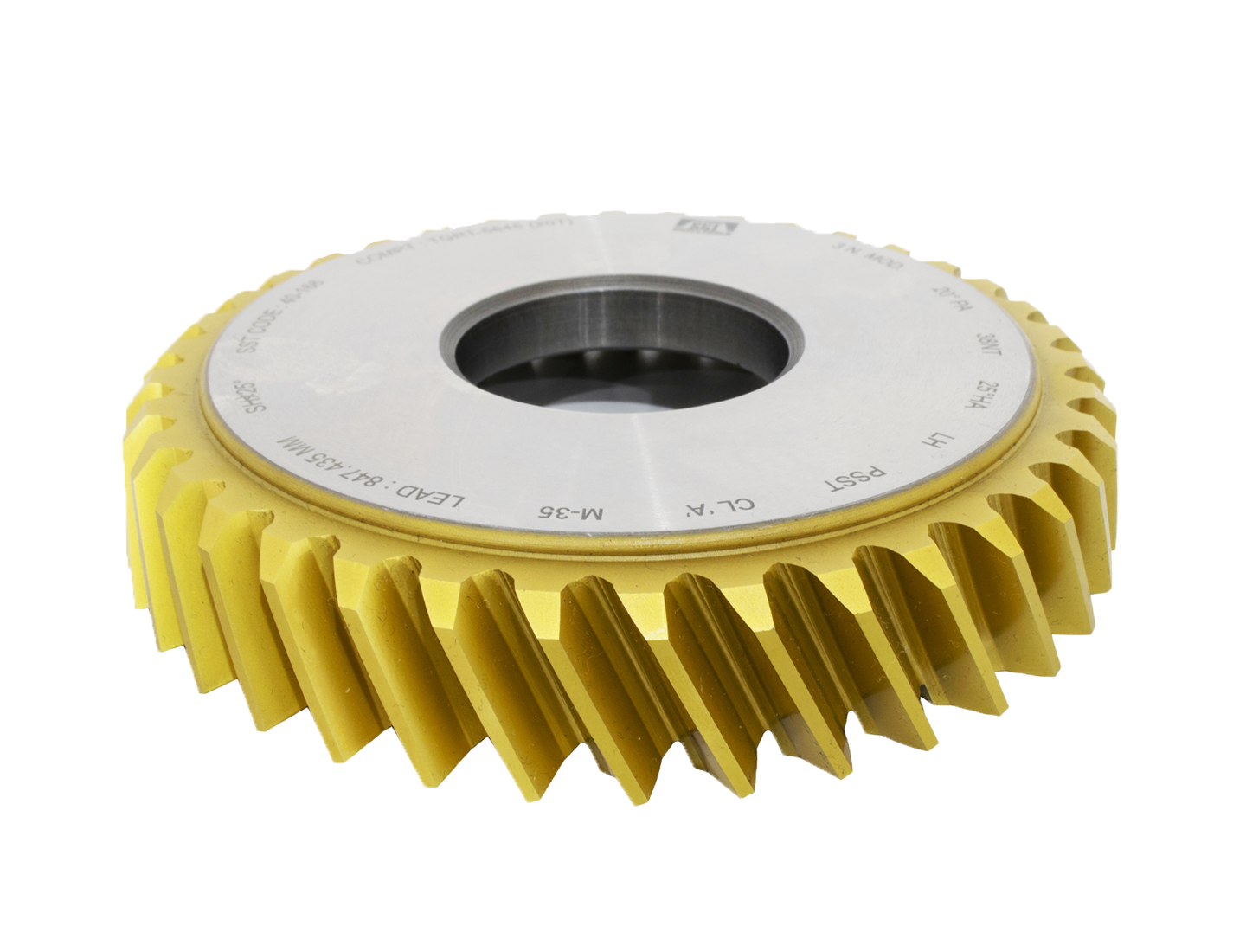

The role of gears is essential in the world of mechanical engineering and manufacturing since gears transfer power and motion efficiently without wastage. Behind every finely tuned gear lies the cutting tool with which the gear could be formed—the gear shaper cutter. What Are Gear Shaper Cutters? Gear shaper cutters are specialized tools for cutting […]

Precision in Motion: Understanding the Role of Gear Shaper Cutters Read More »